The Practical Engineer’s Guide to Getting Power, Efficiency, and Reliability at Sea

Introduction

Engine performance is not about chasing maximum power — it is about delivering the required power, at the right moment, with minimum fuel, minimum stress, and maximum reliability.

In maritime engineering, performance and tuning sit at the intersection of:

- Thermodynamics

- Combustion quality

- Air and fuel delivery

- Control systems

- Human decision-making

Poor performance is rarely caused by one dramatic failure. Instead, it creeps in through small inefficiencies, incorrect settings, aging components, and operational drift.

This page is the Performance & Tuning hub for MaritimeHub. It applies to:

- Two-stroke engines

- Four-stroke engines

- Dual-fuel engines

- Mechanical, electric, and hybrid propulsion

Contents

- What “Performance” Really Means in Marine Engines

- Design Performance vs Operational Performance

- Key Performance Indicators (KPIs) Engineers Actually Use

- The Combustion Triangle (Air – Fuel – Timing)

- Air System Performance (Turbocharging & Scavenging)

- Fuel System Performance

- Mechanical Losses & Friction

- Engine Load, RPM, and Propeller Matching

- Tuning Philosophy: Why Marine ≠ Automotive

- Common Performance Problems & Root Causes

- Engine Tuning Methods (What You Can and Cannot Adjust)

- Four-Stroke vs Two-Stroke Tuning Differences

- Dual-Fuel Performance Considerations

- Performance vs Emissions Trade-offs

- Monitoring, Trend Analysis & Digital Tools

- When NOT to Tune

- Practical Engineer’s Checklist

- What to Learn Next

1. What “Performance” Really Means in Marine Engines

In marine engineering, performance is not peak horsepower.

True performance means:

- Stable power delivery

- Predictable response to load changes

- Acceptable fuel consumption

- Acceptable exhaust temperatures

- Controlled mechanical stress

- Compliance with emissions limits

An engine making slightly less power cleanly will always outlive one making maximum power poorly.

2. Design Performance vs Operational Performance

Design Performance

Set by the manufacturer:

- Rated power (MCR)

- Specific fuel oil consumption (SFOC)

- Air/fuel ratios

- Compression ratios

- Turbocharger maps

This exists on paper and during factory tests.

Operational Performance

What actually happens onboard:

- Fouling

- Wear

- Fuel variability

- Ambient conditions

- Maintenance quality

- Human operation

Most performance issues arise because engines are operated far from their design assumptions.

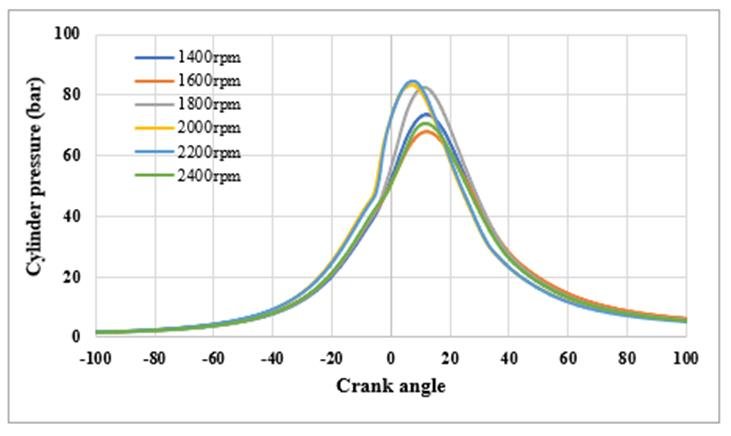

3. Key Performance Indicators (KPIs) Engineers Actually Use

Forget brochures. Engineers watch:

- Brake Mean Effective Pressure (BMEP)

- Specific Fuel Oil Consumption (g/kWh)

- Exhaust Gas Temperature (per cylinder)

- Turbocharger speed

- Scavenge pressure / intake pressure

- Peak firing pressure (Pmax)

- Rate of pressure rise (dp/dθ)

4. The Combustion Triangle

Air – Fuel – Timing

All performance issues trace back to imbalance between:

1️⃣ Air

- Quantity

- Pressure

- Temperature

- Distribution

2️⃣ Fuel

- Injection pressure

- Injection timing

- Atomization quality

- Fuel quality

3️⃣ Timing

- Injection timing

- Valve timing

- Ignition timing (gas engines)

If one side degrades, performance collapses non-linearly.

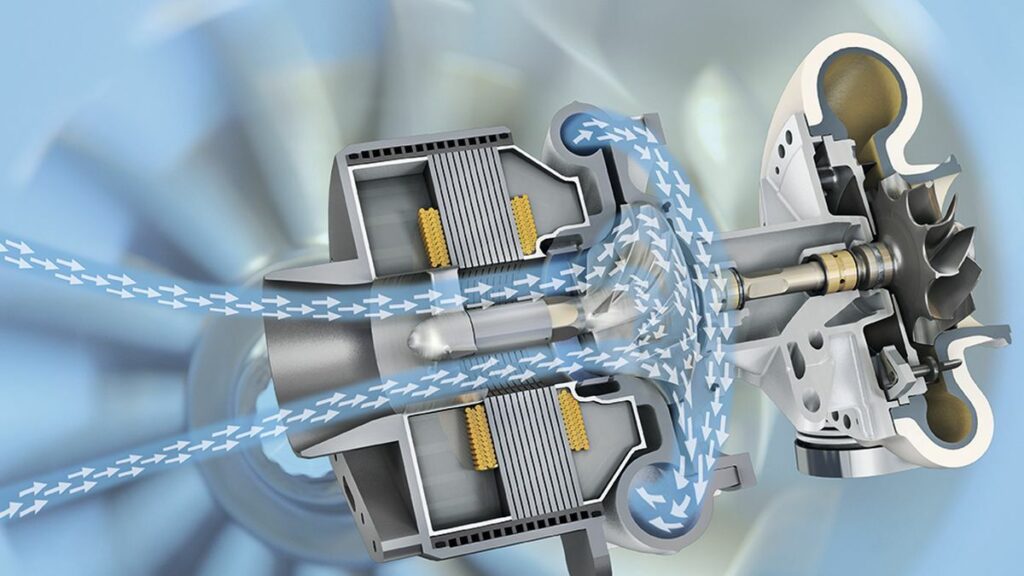

5. Air System Performance (Turbocharging & Scavenging)

Common Air-Side Performance Losses

- Fouled turbocharger compressor

- Eroded turbine blades

- Scavenge air cooler fouling

- Leaking charge air piping

- Incorrect variable nozzle settings

Symptoms

- High exhaust temperatures

- Black smoke

- Slow load acceptance

- Increased fuel consumption

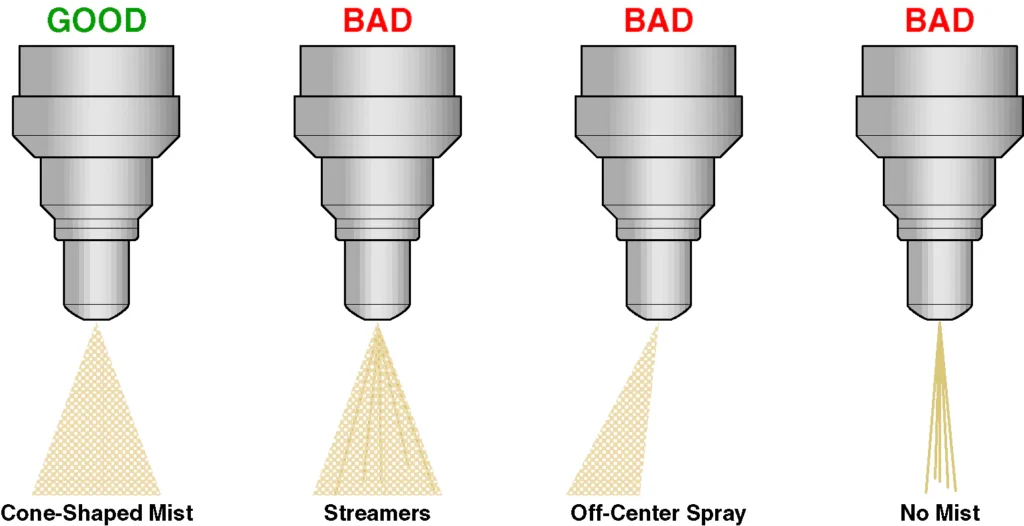

6. Fuel System Performance

Fuel determines how cleanly energy is released.

Key Fuel-Side Factors

- Injection pressure consistency

- Injector nozzle condition

- Fuel viscosity control

- Fuel temperature

- Leak-off balance

Typical Fuel-Related Performance Issues

- Poor atomization → incomplete combustion

- Dribbling injectors → high EGT

- Timing drift → knock or late burn

7. Mechanical Losses & Friction

Even perfect combustion is wasted if mechanical losses rise.

Contributors

- Piston ring wear

- Liner glazing

- Bearing friction

- Incorrect lubrication rate

- Misalignment

These losses show up as:

- Reduced shaft power

- Higher fuel burn

- Rising lube oil temperatures

8. Engine Load, RPM, and Propeller Matching

Many “engine problems” are propeller problems.

Over-Propped Engine

- Cannot reach rated RPM

- High cylinder pressures

- Thermal overload

Under-Propped Engine

- Light running

- Poor efficiency

- Carbon build-up

9. Tuning Philosophy: Why Marine ≠ Automotive

Marine engines are:

- Continuous duty

- Load-driven

- Thermally constrained

Marine Tuning Goals

- Flatten stress peaks

- Improve combustion balance

- Reduce temperature spread

- Protect margins

Not:

- Maximum acceleration

- Peak output

- Aggressive timing

10. Common Performance Problems & Root Causes

| Symptom | Likely Cause |

|---|---|

| High EGT one cylinder | Injector / valve timing |

| Black smoke | Air deficiency |

| White smoke | Poor ignition / cold combustion |

| Knocking | Advanced timing / poor fuel |

| Sluggish response | Turbo lag / fouling |

11. Engine Tuning Methods

(What You Can and Cannot Adjust)

Adjustable (Depending on Engine)

- Injection timing

- Injection pressure

- Fuel rack / governor curves

- Valve clearances

- VGT settings

- Load sharing parameters

NOT Adjustable

- Compression ratio

- Piston geometry

- Fundamental airflow capacity

⚠️ Tuning outside manufacturer limits shortens life dramatically.

12. Four-Stroke vs Two-Stroke Tuning Differences

Two-Stroke

- Scavenge pressure critical

- Exhaust valve timing dominant

- Turbocharger highly sensitive

Four-Stroke

- Valve overlap tuning

- Injection timing more flexible

- Better low-load behavior

13. Dual-Fuel Performance Considerations

Dual-fuel engines add:

- Pilot fuel dependency

- Gas quality sensitivity

- Mode-dependent tuning

Common DF Performance Issues

- Methane slip at low load

- Slow gas response

- Mode switching instability

Performance tuning often involves control logic, not hardware.

14. Performance vs Emissions Trade-Offs

Improving one often worsens the other:

| Action | Performance | Emissions |

|---|---|---|

| Advance timing | ↑ Power | ↑ NOx |

| Lean mixture | ↑ Efficiency | ↑ Misfire risk |

| High EGR | ↓ NOx | ↓ Power |

This is why tuning must respect regulatory envelopes.

15. Monitoring, Trend Analysis & Digital Tools

Modern performance tuning is data-driven.

Engineers track:

- Cylinder-to-cylinder deviation

- Long-term fuel index drift

- Turbo efficiency trends

Digital twins and condition monitoring now outperform manual tuning alone.

16. When NOT to Tune

Do not tune when:

- Root cause is unknown

- Mechanical damage exists

- Air system is compromised

- Sensors are unreliable

Tuning hides problems — it does not fix them.

17. Practical Engineer’s Checklist

Before touching settings:

- ✅ Clean air path

- ✅ Balanced injectors

- ✅ Correct valve clearances

- ✅ Verified sensors

- ✅ Propeller condition known

After tuning:

- 📊 Log changes

- 🔥 Monitor EGT spread

- ⏱ Observe over several voyages

18. What to Learn Next (MaritimeHub)

Continue into:

- Faults & Troubleshooting

- Emissions Control

- Dual-Fuel Systems

- Calculators & Data Sheets

Final Thought

Performance tuning is not about making engines stronger.

It is about:

Making engines calmer, cleaner, and predictable — for thousands of hours.

That is real marine engineering.