ENGINE ROOM → Control & Operations

Position in the Plant

System Group: Control & Operations

Primary Role: Escalating protection logic that prevents a deviation becoming an accident

Interfaces: IAS/AMS · Fire & Gas · Power Management · Propulsion · Cargo Systems · Ventilation · Communication / PA / GA

Operational Criticality: Absolute

Failure Consequence:

- Failure to act → injury, fire escalation, pollution, loss of containment

- Spurious action → blackout, loss of position, cargo surge, structural damage

Alarm, shutdown, and Emergency Shutdown (ESD) systems are not optional features.

They are the engineered boundary between a manageable upset and an unrecoverable casualty.

They exist to protect, in strict order:

- People

- The vessel

- The environment

Their ultimate objective is to force the plant into a safe, static condition when human action is too slow, uncertain, or no longer possible.

Introduction

Ships operate in a regime where time is the enemy.

Abnormal conditions do not arrive as single failures — they develop as trends, interacting faults, and accumulating deviations.

Protection systems therefore operate in layers:

- Alarms demand attention while corrective action is still possible

- Shutdowns remove energy from a local hazard before escalation

- ESD aggressively isolates hazards when escalation risk outweighs operational continuity

This escalation ladder is mandatory, documented, audited, and enforced by flag state, class societies, and vessel-specific risk assessments.

It is normally formalised in a Shutdown Philosophy / Cause & Effect document that defines:

- what initiates action

- what equipment responds

- in what order

- and what must remain operable afterwards

The core truth is simple:

Protection logic is not written to keep the ship running.

It is written to keep the ship survivable.

Contents

- The Layered Protection Model

- Alarm Philosophy – Attention, Not Noise

- Shutdown Philosophy – Controlled Termination Without Cascades

- Emergency Shutdown (ESD) – Safe Static Condition and Hazard Isolation

- Cargo Transfer Emergency Shutdown (ESD-1 & ESD-2)

- Tank Protection and Cargo Overflow Defence

- Gas Burning Safety System (LNG Carriers)

- Independence, Fail-Safe Design & De-Energize-to-Trip

- Cause & Effect, Hierarchy Levels & Reset Discipline

- Overrides, Inhibits & the Reality of Maintenance

- DP Vessels & MODUs – When Safety Can Create New Hazard

- Human Factors, Spurious Trips & Why Buttons Get People Fired

- What Must Remain Operable After Shutdown

1. The Layered Protection Model

Engineering plants do not fail neatly.

A rising temperature could indicate:

- sensor drift

- bearing distress

- cooling flow restriction

- lubrication breakdown

- control valve instability

The system cannot wait for certainty.

The layered model therefore escalates defensively:

- If the crew can correct it → alarm

- If machinery or containment is threatened → shutdown

- If people, structure, or environment are threatened → ESD

This is not automation “being clever”.

It is automation being conservative.

2. Alarm Philosophy – Attention, Not Noise

Alarms are not data displays.

They are demands for action.

In real emergencies, alarms arrive in bursts. Without prioritisation, the operator is flooded at precisely the moment clarity matters most.

A rationalised marine alarm philosophy therefore distinguishes between:

- Alarms – immediate action required

- Warnings – abnormal condition with escalation potential

- Cautions / advisories – awareness only

Acknowledgement is a deliberate safeguard.

It forces the operator to consciously recognise the condition before it can clear.

Alarm Monitoring Systems (AMS) supervise propulsion, power, steering, cargo, bilges, tanks, fire detection, and critical auxiliaries — but the AMS does not “know” what matters. Humans configure it.

A noisy plant trains its crew to ignore warnings.

A quiet plant preserves attention for when it matters.

3. Shutdown Philosophy – Controlled Termination Without Cascades

Shutdowns exist because not all hazards are manageable by intervention.

A correct shutdown philosophy obeys three absolute rules:

Hierarchy

Lower-level shutdowns must not force higher-level trips.

Higher-level shutdowns incorporate lower-level effects.

Predictability

Random shutdown sequences create secondary hazards:

pressure surge, thermal shock, loss of lubrication, blackout, cargo hammer.

No adverse cascade

A shutdown must not rely on another system to prevent catastrophe.

If stopping a pump causes a blackout, the shutdown is unsafe.

Cargo transfer is a prime example: “stop pumping” is not a single action. It is a sequenced isolation that must prevent surge pressure, protect loading arms, and coordinate ship and shore.

4. Emergency Shutdown (ESD) – Safe Static Condition

ESD is the highest protection layer.

Its purpose is not availability.

It is consequence limitation.

Typical ESD objectives:

- isolate hydrocarbons and fuel

- stop prime movers and compressors

- shut ventilation where required

- trip non-essential electrical systems

- coordinate with fire & gas systems

- preserve emergency lighting, comms, PA/GA

ESD may be initiated:

- manually (control room, ECR, evacuation points)

- automatically (fire, gas, critical process signals)

On tankers and gas carriers, ESD is frequently linked ship-to-shore to ensure coordinated termination.

5. Cargo Transfer Emergency Shutdown (ESD-1 & ESD-2)

Cargo ESD systems are a specialised subset of the general philosophy, governed primarily by the IGC Code.

ESD-1 – Cargo Transfer Shutdown

ESD-1 protects the transfer process itself.

Its function is to stop cargo flow and isolate ship and shore systems in a controlled manner.

Typical ESD-1 actions include:

- trip cargo pumps or vapour compressors

- close ship manifold valves within ~25–30 seconds

- close shore ESD valves within terminal-specific timing

- activate alarms on both ship and shore

Because cargo pumps may be kilometres from tanks, kinetic energy and surge pressure dominate the design.

Ship and shore ESD must therefore be linked to ensure coordinated valve closure.

ESD-2 – Emergency Release

ESD-2 addresses loss of physical integrity at the manifold.

It initiates:

- Emergency Release System (ERS) valve closure

- rapid uncoupling of loading arms

- automatic initiation of ESD-1

ESD-2 is designed to protect people and structure when relative ship movement exceeds safe limits.

6. Tank Protection and Cargo Overflow Defence

Tank protection systems operate independently of ESD-1, though functions may overlap.

They protect containment against:

- overfill

- over-pressure

- vacuum

- excessive differential pressure

Modern designs use two independent level systems:

- main CTS gauge (continuous)

- independent “spot” sensors (HHL)

Typical sequence:

- Pre-alarm

- Tank filling valve closure

- ESD-1 initiation

This staged approach ensures protection without nuisance shutdowns.

7. Gas Burning Safety System (LNG Carriers)

The gas burning safety system protects machinery spaces by isolating gas fuel.

Key features:

- master gas fuel valve in cargo area

- manual trip in engine room

- automatic trip on ventilation failure or gas detection

On closure:

- gas fuel compressors stop

- downstream lines are purged with nitrogen

Although often viewed as an engine-room system, it also protects cargo tanks from low-pressure damage.

8. Independence, Fail-Safe Design & De-Energize-to-Trip

A protection system dependent on the system it protects is not protection.

ESD systems are therefore:

- electrically independent

- logically separate

- power-backed by UPS or accumulators

Fail-safe design normally means fail-closed, implemented through:

- spring-return actuators

- hydraulic accumulators

- pneumatic reservoirs

De-energize-to-trip logic reduces failure-to-act risk but increases susceptibility to spurious trips — demanding robust power quality and monitoring.

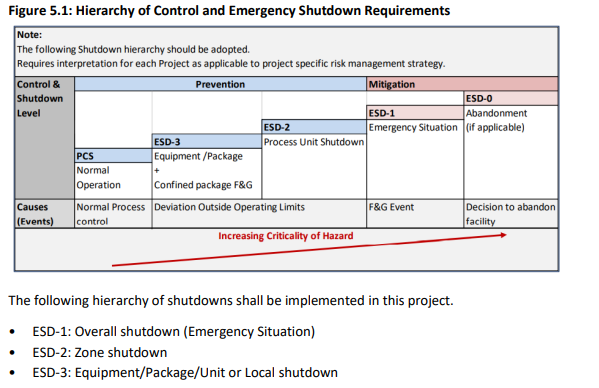

9. Cause & Effect, Hierarchy & Reset Discipline

Cause & Effect charts translate philosophy into logic:

- initiating event

- intermediate logic

- final action

- survivable systems

Reset philosophy is critical.

High-level ESD typically demands local reset to prevent blind re-energisation.

Lower-level shutdowns may permit group reset.

Reset is a high-risk moment.

10. Overrides, Inhibits & Maintenance Reality

Testing and maintenance require bypass capability — but this is where safety systems fail most often.

Best practice requires:

- physical key switches for high-integrity overrides

- clear indication and logging

- administrative control

- automatic cancellation of start-up overrides

A shutdown that can be casually bypassed will eventually be bypassed permanently.

11. DP Vessels & MODUs – When Safety Creates Hazard

On DP vessels, blackout is not inconvenience.

It is loss of position, collision risk, loss of well control.

History shows ESD-induced blackouts caused by:

- accidental button activation

- testing errors

- voltage dips

- poor reset philosophy

The solution is not removing ESD.

It is engineered staging, protected activation, and deliberate initiation of highest-level shutdowns.

12. Human Factors & Spurious Trips

Most catastrophic trips are not equipment failures.

They are human-system interface failures.

Mitigations include:

- guarded pushbuttons

- two-step activation

- clear differentiation from routine stops

- disciplined training and access control

The goal is not to make ESD difficult.

It is to make unintentional ESD nearly impossible.

13. What Must Remain Operable After Shutdown

Shutdown does not mean dead ship.

Typically required survivable systems:

- emergency lighting

- PA / GA

- radio communications

- navigation aids

- emergency generator

A safe static condition still requires coordination, evacuation, and command.

Closing Reality

Alarms protect time.

Shutdowns protect machinery and containment.

ESD protects life and the environment — but can create new hazards if poorly applied.

The most dangerous plant is not one without shutdowns.

It is one with shutdown logic nobody fully understands.