Corrosion Control, Scale Prevention, and Chemical Stability in Marine Water Systems

System Group: Cooling & Heat Transfer

Primary Role: Preservation of metal integrity, heat transfer efficiency, and pressure boundary life

Applies To: Boilers · HT/LT Cooling · Central Cooling · Auxiliary Systems · Offshore & Yacht Plants

Interfaces: Heat Exchangers · Boilers & Steam Systems · Fresh Water Generation · Blowdown Systems

Operational Criticality: Continuous

Failure Consequence: Accelerated corrosion → scale formation → heat transfer collapse → tube failure → plant damage or shutdown

Water chemistry is not a background maintenance task.

It is the silent determinant of how long machinery survives.

Contents

- System Purpose and Design Intent

- Why Water Becomes Aggressive in Marine Plants

- Closed-Loop Water Systems and the Steam–Condensate Cycle

- Chemical Control Philosophy and Responsibility

- Major Water Chemistry Parameters and Their Control

5.1 pH Control

5.2 Phosphate Control

5.3 Oxygen Scavenging (Hydrazine / Alternatives)

5.4 Chloride Control

5.5 P & M Alkalinity - Boiler Water Testing Architecture and Equipment

- Step-by-Step Boiler Water Test Procedures (Operational Reality)

- Cooling Water Chemistry Beyond the Boiler

- Failure Development and Damage Progression

- Human Oversight, Sampling Discipline, and Engineering Judgement

1. System Purpose and Design Intent

Water in marine systems is never neutral.

Once heated, pressurised, circulated, and exposed to metals, water becomes chemically aggressive. It dissolves gases, strips protective films, transports ions, and accelerates corrosion reactions that would otherwise take decades ashore.

The purpose of water chemistry control is not to make water “safe”.

It is to slow inevitable damage to a manageable rate.

Untreated or poorly treated water leads to:

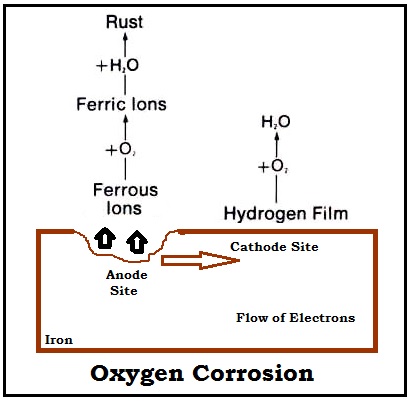

- oxygen corrosion

- caustic attack

- scale deposition

- under-deposit corrosion

- tube overheating

- pressure boundary failure

Water chemistry determines whether boilers and cooling systems last months, years, or decades.

2. Why Water Becomes Aggressive in Marine Plants

Marine water systems operate under extreme conditions:

- high temperature

- cyclic pressure

- constant evaporation and concentration

- repeated contamination risk

As water is converted to steam, impurities concentrate. As steam condenses, it scavenges oxygen and carbon dioxide from air leaks. As condensate returns, it carries that damage back into the boiler.

Water does not need to be dirty to be destructive.

Pure water is often the most corrosive.

3. Closed-Loop Water Systems and the Steam–Condensate Cycle

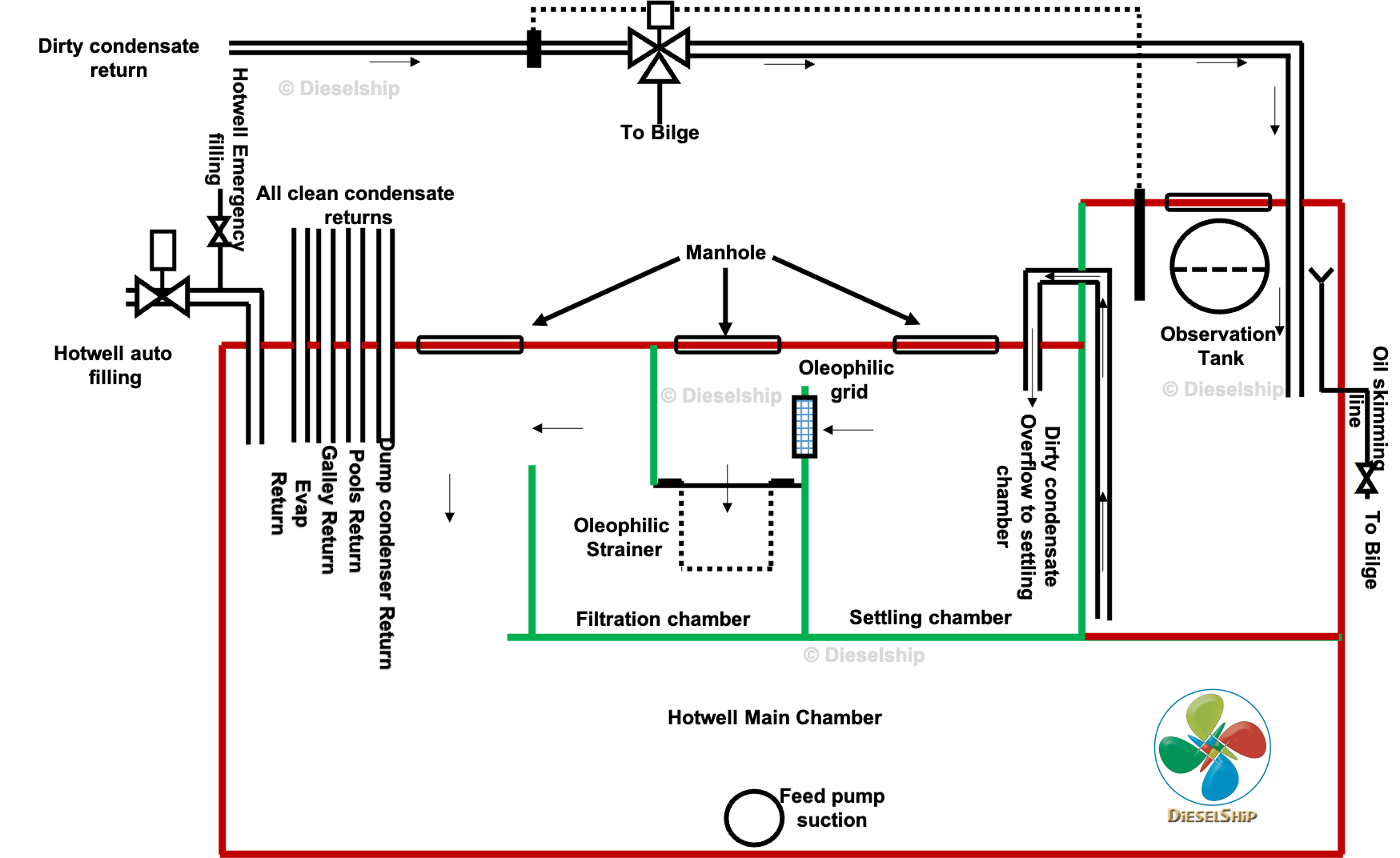

Boiler feed water is distilled water that has been chemically conditioned.

In operation:

- water is heated into steam

- steam performs work (turbines, heating, tracing)

- steam condenses in condensers or heaters

- condensate collects in hotwells or cascade tanks

- feed pumps return it to the boiler

This loop appears closed — but it never truly is.

Air ingress, makeup water, condenser leaks, and chemical reactions constantly alter water composition.

4. Chemical Control Philosophy and Responsibility

Onboard water chemistry is often delegated to junior engineers — but responsibility is collective.

Testing is procedural. Interpretation is not.

Chemical dosing does not “fix” problems. It manages risk:

- inhibitors slow corrosion

- phosphates redirect hardness

- scavengers remove oxygen

- alkalinity buffers reactions

Overdosing is as dangerous as neglect.

5. Major Water Chemistry Parameters and Their Control

5.1 pH Control

pH defines whether water attacks metal or allows scale to form.

Boiler water must be maintained alkaline, typically:

- 9.5 – 11.5 pH

Low pH causes:

- acidic corrosion

- metal thinning

- rapid tube attack

Excessively high pH causes:

- caustic embrittlement

- foaming

- carryover

pH control also determines whether other treatment chemicals function correctly.

5.2 Phosphate Control

Phosphate reacts with calcium hardness to form soft sludge instead of hard scale.

This sludge settles in low-flow areas and can be removed by bottom blowdown.

Target phosphate range is typically:

- 20 – 50 ppm

Too little phosphate allows scale to form.

Too much increases solids loading and foaming risk.

5.3 Oxygen Scavenging (Hydrazine and Alternatives)

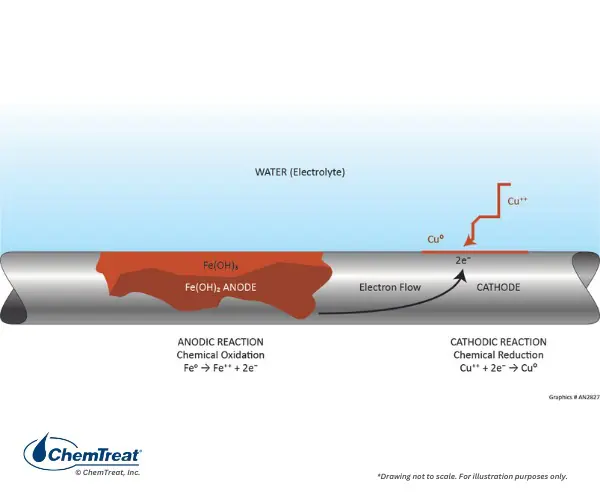

Dissolved oxygen is the primary driver of corrosion.

Hydrazine reacts with oxygen to form nitrogen and water, removing oxygen before it can attack steel.

Typical target range:

- 0.1 – 0.2 ppm

Excess scavenger is wasteful and hazardous.

Insufficient scavenger allows rapid pitting.

Modern plants may use alternative oxygen scavengers, but the chemistry objective remains the same.

5.4 Chloride Control

Chlorides indicate seawater contamination.

They increase electrical conductivity, accelerating corrosion and promoting stress cracking.

Typical maximum limit:

- ≤ 50 ppm

There is no chemical treatment to remove chlorides onboard.

The only correction is:

- blowdown

- replacement with low-chloride distilled feed water

- identification of contamination source

5.5 P & M Alkalinity

Alkalinity represents the water’s ability to buffer acidic reactions.

- P Alkalinity relates to hydroxide and phosphate alkalinity

- M Alkalinity represents total alkalinity

These values indicate whether the boiler environment supports:

- corrosion protection

- controlled precipitation

- chemical stability

Alkalinity that is too low allows corrosion.

Too high encourages foaming and carryover.

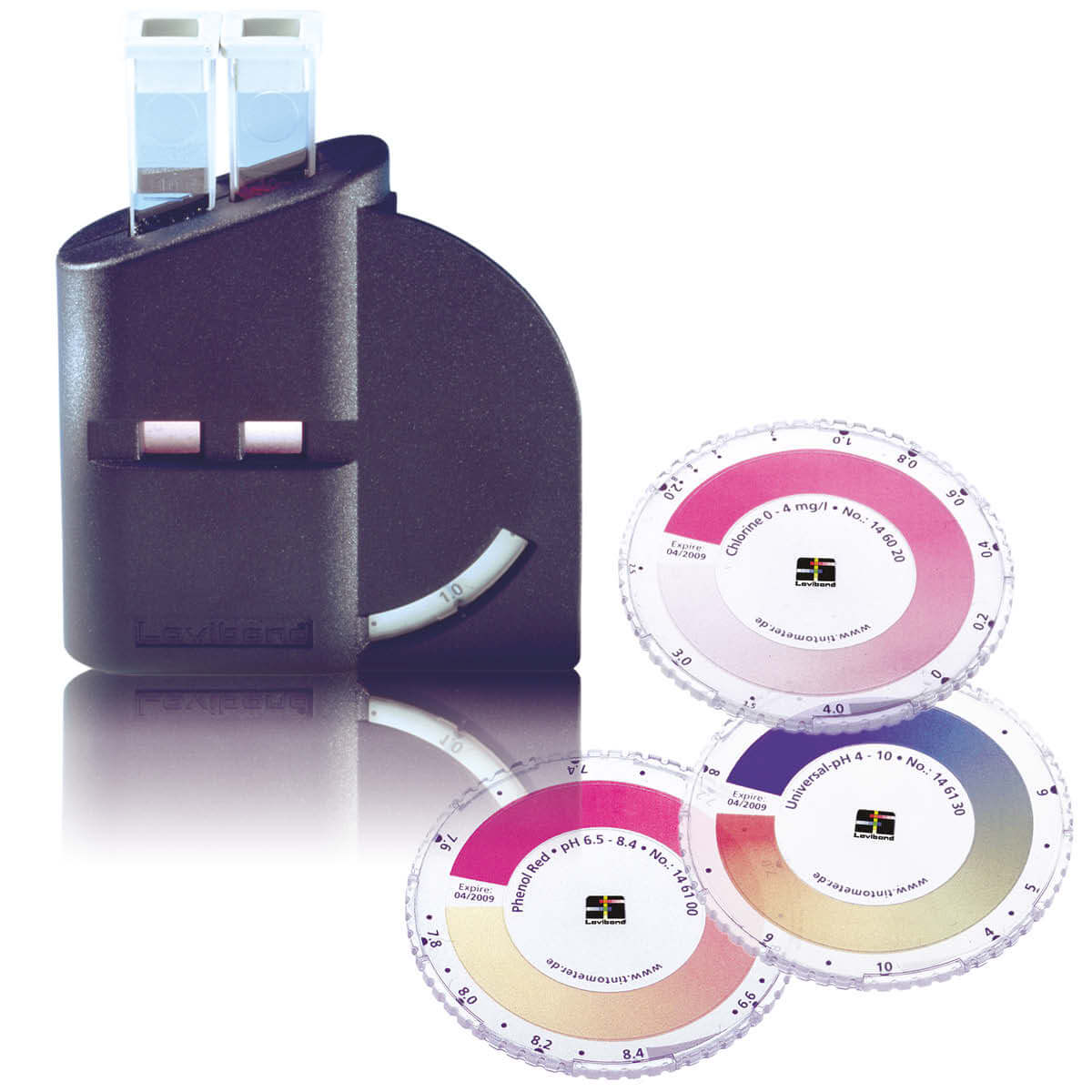

6. Boiler Water Testing Architecture and Equipment

Testing kits vary by supplier, but all follow the same principles.

A typical marine boiler water test kit includes:

- calibrated sample beakers

- comparator vials

- reagent tablets

- indicator discs

- filters and crushers

The kit is not the control system — it is the diagnostic interface.

7. Step-by-Step Boiler Water Test Procedures (Operational Reality)

pH Test

Sample is treated with reagent and indicator strip to determine alkalinity.

Phosphate Test

Comparator method identifies phosphate concentration after tablet dissolution.

Hydrazine Test

Colorimetric reaction indicates oxygen scavenger residual.

Chloride Test

Tablet titration reveals seawater contamination level.

P & M Alkalinity Test

Sequential indicator tablets determine buffering capacity.

Procedures are simple. Trend interpretation is not.

A single result is meaningless without history.

8. Cooling Water Chemistry Beyond the Boiler

HT/LT cooling water requires:

- nitrite or equivalent inhibitors

- controlled pH

- very low chloride levels

Nitrite levels are typically maintained between:

- 700 – 2400 ppm NO₂

Cooling water chemistry failures often present as:

- unexplained temperature rise

- increased corrosion products

- heat exchanger fouling

9. Failure Development and Damage Progression

Water chemistry failures are slow, silent, and cumulative.

Typical progression:

- Minor chemistry drift

- Accelerated corrosion or scale formation

- Heat transfer loss

- Local overheating

- Tube failure or leakage

- Contamination cascade

By the time alarms activate, damage is already embedded.

10. Human Oversight, Sampling Discipline, and Engineering Judgement

Automation cannot sample water.

Engineers must:

- sample consistently

- test accurately

- log trends

- interpret deviations

- act conservatively

Skipping tests does not save time — it borrows failure from the future.