Introduction

Emissions control in maritime engineering is no longer a regulatory side topic — it is a core design, operational, and maintenance discipline.

Modern marine engineers must understand:

- What emissions are produced

- Why they are produced

- How regulations limit them

- How technology reduces them

- What trade-offs are unavoidable

Contents (Jump Links)

- Why Emissions Matter at Sea

- The Five Main Marine Engine Emissions

- How Emissions Are Formed (Combustion Science)

- IMO Regulations Explained (MARPOL Annex VI)

- NOx Control Technologies

- SOx Control Technologies

- Particulate Matter (PM) Control

- CO₂ Reduction Strategies

- Methane Slip (Dual-Fuel Reality)

- Exhaust Gas Recirculation (EGR)

- Selective Catalytic Reduction (SCR)

- Scrubbers (Open, Closed & Hybrid)

- Fuel-Based Emissions Control

- Emissions vs Engine Performance Trade-Offs

- Operational Emissions Management

- Monitoring, Sensors & Compliance

- Common Emissions-Related Faults

- What to Learn Next (MaritimeHub Links)

1. Why Emissions Matter at Sea

Shipping moves 80–90% of global trade, but it also produces:

- ~3% of global CO₂ emissions

- Significant shares of global NOx and SOx

- Concentrated pollution near ports and coastlines

Unlike land transport, ships:

- Operate continuously

- Burn large quantities of fuel

- Cannot easily stop or reroute

Emissions control is therefore enforced through engineering solutions, not traffic restrictions.

2. The Five Main Marine Engine Emissions

1️⃣ Nitrogen Oxides (NOx)

Formed at high combustion temperatures.

- Increases with peak temperature

- Increases with advanced timing

- Regulated by IMO Tier I / II / III

2️⃣ Sulfur Oxides (SOx)

Directly linked to fuel sulfur content.

- Independent of engine design

- Controlled via fuel choice or scrubbers

3️⃣ Carbon Dioxide (CO₂)

Proportional to fuel burned.

- Cannot be “cleaned”

- Only reduced via efficiency or fuel change

4️⃣ Particulate Matter (PM)

Includes soot and ash.

- Poor atomization

- Incomplete combustion

- Heavy fuels

5️⃣ Methane (CH₄)

Relevant to dual-fuel gas engines.

- Unburned methane = methane slip

- High global warming potential

| Emission | Primary Origin in Engine | How It Forms | Key Influencing Factors | Engine Type Sensitivity | Primary Control Methods |

|---|---|---|---|---|---|

| NOx (Nitrogen Oxides) | Combustion chamber (flame zone) | High-temperature reaction between nitrogen and oxygen when peak cylinder temperatures exceed ~1800 K | • Peak combustion temperature• Injection timing• Excess air ratio• Compression ratio• Load level | High in all diesel enginesEspecially high in slow-speed two-strokes | • Injection timing retard• EGR• SCR• Water injection |

| SOx (Sulfur Oxides) | Exhaust gas (post-combustion) | Sulfur in fuel oxidizes during combustion | • Fuel sulfur content only | Independent of engine design | • Low-sulfur fuel• Scrubbers (EGCS) |

| CO₂ (Carbon Dioxide) | Combustion chamber | Complete oxidation of carbon in fuel | • Fuel consumption• Engine efficiency• Operating load | All engines | • Efficiency improvement• Slow steaming• Alternative fuels |

| PM (Particulate Matter / Soot) | Combustion chamber (fuel spray zones) | Incomplete combustion in locally rich or low-oxygen regions | • Poor atomization• Low air excess• Cold combustion• Fuel quality | High in heavy-fuel enginesMedium-speed engines sensitive | • Injection optimization• Air system maintenance• Fuel quality |

| CO (Carbon Monoxide) | Combustion chamber | Incomplete oxidation of carbon due to insufficient oxygen or poor mixing | • Low load operation• Cold running• Poor scavenging | More prominent at low load | • Load management• Improved air supply |

| Unburned HC | Combustion chamber & crevice volumes | Fuel trapped in crevices or quenched flame zones | • Low temperature• Poor ignition• Wall wetting | Gas and DF engines | • Combustion optimization |

| Methane (CH₄) | Combustion chamber & exhaust (DF engines) | Unburned methane passes through cylinder during gas operation | • Low load• Otto-cycle operation• Incomplete flame propagation | High in DF gas engines | • Combustion mode optimization• Exhaust oxidation catalysts |

| Ammonia Slip (NH₃) | SCR system outlet | Excess urea injection not fully reacted in catalyst | • Incorrect dosing• Low exhaust temperature | Engines with SCR | • SCR tuning• Catalyst temperature control |

| N₂O (Nitrous Oxide) | SCR system (minor) | Side reaction in catalytic systems | • Catalyst chemistry• Operating temperature | Minimal but regulated | • Catalyst design |

| Black Carbon | Exhaust plume (PM fraction) | High-energy soot particles from incomplete combustion | • Fuel type• Load• Combustion quality | High in Arctic operations | • Fuel switching• PM reduction |

3. How Emissions Are Formed (Combustion Science)

NOx Formation

- Temperature-driven

- Peak flame temperature > ~1800 K

- Strongly affected by timing and air excess

SOx Formation

- Sulfur in fuel → sulfur oxides

- No combustion dependency

PM Formation

- Poor fuel spray

- Low oxygen zones

- Cold combustion areas

CO₂ Formation

- Direct carbon balance

- Every kg of fuel burned produces a fixed CO₂ mass

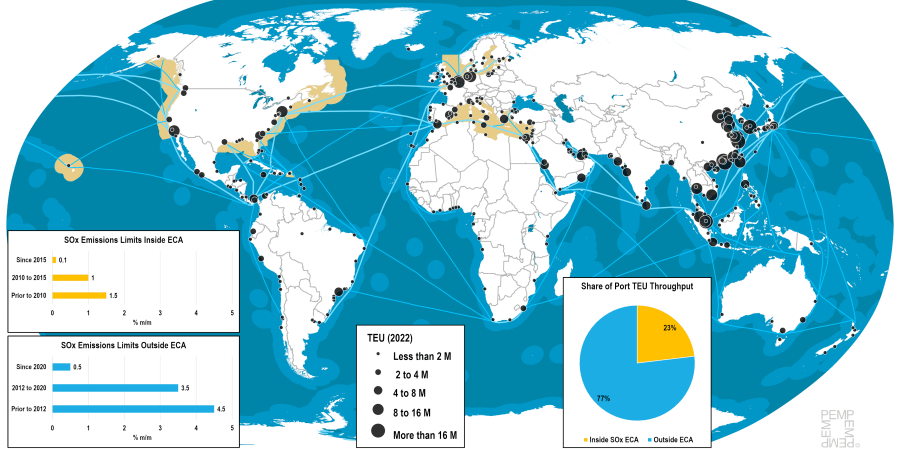

4. IMO Regulations Explained (MARPOL Annex VI)

NOx Tiers

| Tier | Application |

|---|---|

| Tier I | Pre-2000 |

| Tier II | Global standard |

| Tier III | ECAs only |

Sulfur Limits

- Global: 0.50% sulfur

- ECA: 0.10% sulfur

Key ECAs

- Baltic Sea

- North Sea

- North America

- US Caribbean

Compliance is enforced through:

- Documentation

- Sampling

- Continuous monitoring

5. NOx Control Technologies

NOx reduction strategies aim to lower combustion temperature or neutralize NOx downstream.

Two broad categories:

- In-cylinder control

- After-treatment

6. SOx Control Technologies

SOx control is simpler but operationally heavy.

Two approaches:

- Low-sulfur fuel

- Scrubbers

SOx emissions scale almost linearly with fuel sulfur content.

7. Particulate Matter (PM) Control

PM reduction methods include:

- Improved injection

- Higher injection pressure

- Cleaner fuels

- Optimized air supply

PM is often a symptom, not a primary target.

8. CO₂ Reduction Strategies

CO₂ cannot be removed — only avoided.

Main reduction levers:

- Improved efficiency

- Waste heat recovery

- Hybridization

- Alternative fuels

- Speed reduction (slow steaming)

9. Methane Slip (Dual-Fuel Reality)

Methane slip occurs when:

- Gas is not fully combusted

- Engines operate at low load

- Otto-cycle gas operation is used

Methane has ~28× the GWP of CO₂.

Reducing methane slip often increases NOx, creating a tuning conflict.

10. Exhaust Gas Recirculation (EGR)

Principle

- Recirculate exhaust gas

- Reduce oxygen concentration

- Lower peak combustion temperature

Advantages

- Effective NOx reduction

- In-cylinder solution

Disadvantages

- Increased soot

- Acidic contamination

- Higher maintenance burden

11. Selective Catalytic Reduction (SCR)

Principle

- Inject urea (AdBlue)

- Convert NOx → N₂ + H₂O

- Requires correct exhaust temperature

Advantages

- High NOx reduction (>90%)

- Does not affect combustion

Disadvantages

- Urea logistics

- Catalyst fouling

- Space requirements

12. Scrubbers (Open, Closed & Hybrid)

Open Loop

- Uses seawater alkalinity

- Discharge overboard

Closed Loop

- Uses chemical additives

- Waste retained onboard

Hybrid

- Switchable modes

Scrubbers reduce SOx but:

- Increase power consumption

- Add system complexity

- Face port restrictions

13. Fuel-Based Emissions Control

Low-Sulfur Fuels

- Immediate compliance

- Higher cost

- Lubricity concerns

LNG

- Very low SOx

- Lower NOx

- Methane slip risk

Methanol

- Low SOx & PM

- Lower energy density

- Toxic handling

Biofuels

- Drop-in compatibility

- Lifecycle CO₂ benefits

- Feedstock constraints

14. Emissions vs Engine Performance Trade-Offs

| Action | Emissions | Performance |

|---|---|---|

| Retard timing | ↓ NOx | ↓ Efficiency |

| Increase EGR | ↓ NOx | ↑ Soot |

| SCR tuning | ↓ NOx | Neutral |

| Lean burn | ↓ CO₂ | Stability risk |

There is no free solution — only managed compromises.

15. Operational Emissions Management

Engineers influence emissions daily through:

- Load management

- Proper warm-up

- Avoiding cold running

- Cleaning air paths

- Maintaining injectors

Bad operation can defeat the best technology.

16. Monitoring, Sensors & Compliance

Key monitored parameters:

- NOx sensors

- Differential pressure (SCR / scrubber)

- Urea consumption

- Fuel sulfur logs

- Exhaust temperatures

17. Common Emissions-Related Faults

| Symptom | Likely Cause |

|---|---|

| High NOx | SCR inactive / EGR failure |

| White deposits | Urea crystallization |

| Rising backpressure | Scrubber fouling |

| High PM | Poor combustion |

| Methane alarms | DF misfire / low load |

18. What to Learn Next (MaritimeHub)

Continue into:

- Performance & Tuning

- Dual-Fuel Engines

- Faults & Troubleshooting

- Environmental Regulations

- Hybrid & Electric Propulsion

Final Thought

Emissions control is not about passing inspections.

It is about:

Engineering engines that can operate cleanly, reliably, and predictably — across decades of service.

A clean engine is usually a well-understood engine.