Systems, Architectures, Must-Knows, Efficiency, Safety, and Typical Faults

Introduction

Marine propulsion is moving from “engine + gearbox + propeller” toward power systems engineering: generators, converters, energy storage, automation, and software decide how efficiently the ship moves.

Electric and hybrid propulsion is not “one thing.” It’s a family of architectures used to solve different problems:

- Reduce emissions and fuel burn at partial load and during manoeuvring

- Improve redundancy and availability (especially DP vessels)

- Enable quiet / low-vibration operation (comfort + sensitive areas)

- Support shore charging and zero-emission harbour modes

- Integrate new energy sources (batteries, fuel cells, alternative fuels)

IMO’s GHG work and the industry push toward decarbonisation is a major driver, with the Fourth IMO GHG Study and subsequent strategy work shaping the urgency and direction of change. International Maritime Organization+1

Contents (jump links)

- 1. What “Electric” and “Hybrid” really mean

- 2. Where electric/hybrid fits in real shipping

- 3. The main architectures (with diagrams)

- 4. Core components and what they do

- 5. Efficiency: where hybrid wins (and where it doesn’t)

- 6. Control: PMS vs EMS vs “mode management”

- 7. Batteries on ships: design + safety reality

- 8. Fuel cells onboard: where they fit

- 9. Shore charging + ports: practical considerations

- 10. Typical faults and troubleshooting patterns

- 11. Maintenance routines (what good looks like)

- 12. Trends (2020s → 2030s): what’s actually happening

- 13. Quick glossary

- 14. FAQs

- 15. What to learn next (MaritimeHub link map)

1) What “Electric” and “Hybrid” really mean

Electric propulsion means the propeller is driven by an electric motor. The electricity may come from diesel generators, batteries, shore power, fuel cells, or a mix.

Hybrid means the ship has two or more ways to provide propulsion power (or the propulsion power is supported by energy storage). Hybrid can be mechanical + electric, or electric + storage, or electric + fuel cells, etc.

A simple rule:

- Diesel-electric = engine(s) → generator(s) → electric motor → propeller

- Hybrid mechanical = main engine mechanically drives shaft, but there is also a motor/generator on the shaft (PTO/PTI) and often batteries

- Hybrid electric = electric propulsion plus batteries/fuel cells that change how generators run

2) Where electric/hybrid fits in real shipping

Electric/hybrid is strongest where the ship spends time:

- Low load / variable load (tugs, ferries, offshore support, DP, research vessels)

- In ECAs / near ports (harbour mode, manoeuvring, hotel load)

- With high hotel load (cruise, large passenger)

- Where redundancy matters (DP classes, naval, critical operations)

Fully electric is currently most natural for short routes with dependable charging windows—ferries are the headline example (e.g., Norway’s MF Ampere helped demonstrate the concept and operational model).

3) The main architectures

3.1 Conventional mechanical

Fuel → Main Engine → Gearbox/CPP/FPP → Shaft → Propeller

↘ Aux Generators → Ship Electrical Loads

Pros: best peak efficiency at design point, simple, cheap

Cons: poor efficiency at low load, less flexible, harder “zero-emission” manoeuvres

3.2 Diesel-electric (classic electric propulsion)

Fuel → DG1/DG2/DG3 → Main Switchboard (AC) → Drives/VFD → Propulsion Motor → Propeller

↘ Hotel Loads / Aux Systems

Pros: flexible power sharing, good redundancy, engines can be scheduled near efficient load bands

Cons: more conversion losses, more equipment, more control complexity

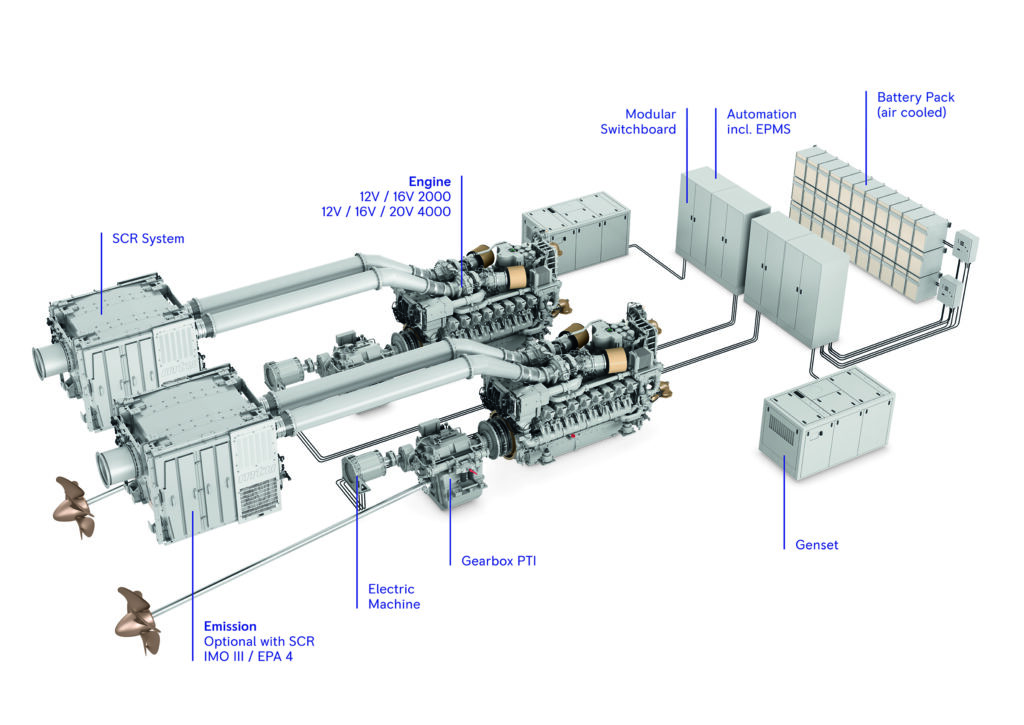

3.3 Parallel hybrid (shaft motor + main engine)

Fuel → Main Engine → Gearbox → Shaft → Propeller

↑

PTI/PTO Motor-Generator ↔ Converter ↔ Electrical Bus ↔ DGs / Batteries

Key capability:

- PTO (Power Take-Off): shaft drives generator to supply ship’s electrical needs

- PTI (Power Take-In): motor adds torque to shaft (boost, smoothing, or low-speed electric mode)

3.4 Series hybrid (engine never mechanically drives the propeller)

Fuel → Gensets → DC/AC Bus ↔ Batteries ↔ Converter → Propulsion Motor → Propeller

Good when: loads vary wildly; you want engines running only when needed, at efficient points

3.5 DC grid architecture (increasingly common)

DGs (variable speed) → Rectifiers → DC Bus ↔ Batteries ↔ DC/DC

↘ Inverters → Motors / AC Loads

Why DC matters: allows variable-speed gensets and often reduces some conversion penalties, but protection and converter reliability become critical.

4) Core components and what they do

4.1 Prime movers (DGs / main engines)

- In hybrid systems, engines should be run in fewer units at higher load rather than many units at low load.

- Bad practice: 3 gensets online “just in case” at 20–30% each → higher SFOC, wet stacking risks, soot, maintenance pain.

4.2 Electric machines (propulsion motors, shaft machines)

- Most propulsion motors are AC machines fed by VFDs.

- Your “engine response” becomes drive response, plus power availability on the bus.

4.3 Power electronics (VFDs, rectifiers, inverters)

These are the heart of the system and the #1 source of “weird faults”:

- DC link undervoltage/overvoltage trips

- Cooling issues

- Harmonics / power quality problems

- Control board faults

- Insulation/ground faults downstream causing drive trips

4.4 Batteries (ESS) and BMS

The ESS is not “a battery.” It’s a system:

- Cells → modules → racks → containers/rooms

- BMS (Battery Management System) for voltage/temperature balancing, limits, alarms

- Cooling and ventilation

- Fire detection/suppression strategy

- Isolation monitoring

4.5 PMS / EMS / automation

- PMS decides how many gensets run, load sharing, blackout recovery logic

- EMS optimises when batteries charge/discharge, when to start/stop DGs, and mode transitions

5) Efficiency: where hybrid wins (and where it doesn’t)

Hybrid/electric isn’t magic—efficiency depends on operating profile.

Where it wins

- Low/variable load: batteries absorb peaks, engines run steadier

- Manoeuvring / harbour: electric mode reduces emissions and noise locally

- DP operations: batteries handle fast transients better than engines

- Hotel-load heavy ships: power can be shared and scheduled intelligently

Where it can lose

- Continuous high-speed ocean transit at near MCR: mechanical direct drive can be hard to beat because electric paths add conversion losses (generator + converters + motor).

Practical metric mindset

Instead of arguing “electric vs mechanical,” evaluate:

- Time at low load (harbour/DP/slow steaming)

- Peak shaving needs (thrusters, cranes, DP spikes)

- Redundancy requirement (DP class, mission critical)

- Fuel/energy price + shore power availability

- Regulatory constraints (local zero-emission zones, port rules)

6) Control: PMS vs EMS vs “mode management”

Most operational pain happens at transitions.

Typical operating modes

- Transit (efficient): DG scheduling + battery smoothing

- Manoeuvring: instant torque demand, thrusters online, bus stability critical

- Harbour / zero-emission: batteries/shore power, gensets off

- DP: redundancy high, spinning reserve logic, fast load steps

- Emergency: blackout recovery, load shedding priorities

The 3 common failure patterns

- Wrong mode or wrong limits (human or automation logic)

- Power margin too tight (DGs slow to pick up load; batteries not available due SOC/temperature limits)

- Protection coordination issues (one trip cascades into “everything trips”)

7) Batteries on ships: design + safety reality

Why lithium-ion dominates

Li-ion tends to win on energy density and maturity for marine ESS, but the real decision is chemistry + packaging + safety case.

The true engineering constraints

- SOC window: you rarely use 0–100% in practice

- Thermal management: cooling failure = rapid derating or escalating risk

- Fire strategy: detection, containment, ventilation shutdown logic, and re-ignition planning

- Fault handling: isolation faults, cell imbalance, rack disconnects

Real-world example (fully electric ferry)

Projects like Norway’s MF Ampere are widely cited as early proof that short-route electric can work with shore charging and the right operational model.

8) Fuel cells onboard: where they fit

Fuel cells are attractive because they convert fuel to electricity efficiently with very low local emissions—but they bring fuel logistics and system complexity.

Where fuel cells make sense first

- Short routes or controlled corridors where hydrogen supply is realistic

- Vessels where silent/clean operation is a strong value (research, sensitive areas)

- Hybridised systems where fuel cells provide steady base load, with batteries handling transients

Key engineering challenge

- Fuel storage (especially hydrogen), space, safety, and crew competence

- Stack life and degradation management

- Integration with DC bus and power converters

9) Shore charging + ports: practical considerations

Shore charging is often the “secret sauce” for big savings on short routes.

What actually matters:

- Connection time available (minutes vs hours)

- Peak charging power vs port grid capability

- Cable management / automatic connection systems

- Demand charges and energy tariffs

- Operational discipline (charging every cycle vs “when convenient”)

10) Typical faults and troubleshooting patterns

10.1 Fast triage (what failed?)

A) Propulsion motor stopped

- Did the drive trip?

- Did the bus collapse?

- Did the PMS shed propulsion?

- Is there a cooling interlock?

B) System de-rated / limp mode

- Battery SOC/temperature limit?

- Converter cooling limitation?

- Generator overload margin?

- Thrust limitation due to protection?

C) Blackout / near-blackout

- Load step exceeded spinning reserve?

- DG failed to pick up load (air/fuel/governor)?

- Protection tripped healthy sections (coordination issue)?

10.2 Common fault patterns table

| Symptom | Likely cause (top hits) | Checks (in order) |

|---|---|---|

| Propulsion VFD trips on DC link undervoltage | Genset droop response slow, battery unavailable, sudden load step | PMS event log → SOC & battery status → DG load share → bus voltage trend |

| VFD trips on overcurrent on acceleration | Propeller load spike, torque limit wrong, motor insulation issue | Torque limit settings → shaft line binding → motor IR/PI test (when safe) |

| Repeated earth fault / insulation alarm | Cable moisture, motor winding deterioration, converter leakage | IR/IMD readings → isolate sections → inspect terminations/water ingress |

| Harmonics / overheating transformers | Nonlinear loads + poor filtering, VFD issues | THD measurements → filter status → converter fault codes |

| Battery “not available” | SOC low, temp high/low, BMS alarm, cooling fault | BMS alarms → HVAC/chiller → SOC limits → contactor status |

| Genset trips when thrusters start | Insufficient spinning reserve, wrong load-shedding priorities | PMS settings → load-shed table → DG ramp rate/governor response |

| DC bus instability | Converter control interaction, wrong droop settings, weak source | EMS/PMS tuning review → converter firmware → protection coordination |

10.3 The “hybrid-specific” faults engineers see

- Mode confusion (PTI enabled when it shouldn’t be; PTO loading the shaft during manoeuvring)

- SOC management failure (arrive port with empty battery = no electric manoeuvre)

- Cooling dependency (one seawater issue derates half the electrical plant)

- Automation trust gap (crew bypasses logic → system becomes unpredictable)

11) Maintenance routines

Daily/Watchkeeping mindset

- Trend bus voltage/frequency, converter temps, cooling delta-T

- Trend DG load distribution (avoid chronic low-load running)

- Record battery SOC, rack temperatures, and BMS warnings

- Confirm alarms are not “normalized” (hybrid plants punish ignored alarms)

Weekly/Monthly

- Verify load shedding priorities still match operational reality

- Check converter cooling circuits, filters, fan health, heat exchangers

- Inspect electrical spaces for humidity control and contamination

- Test blackout recovery logic (as permitted by vessel procedures)

Drydock / periodic

- Insulation testing and partial discharge checks where applicable

- Motor bearing inspection (especially if VFD-induced bearing currents are a known risk)

- Converter firmware and parameter management (change control!)

12) Trends (2020s → 2030s): what’s actually happening

What’s “real” in the market:

- More batteries (especially ferries, tugs, offshore) because they solve transients and enable harbour compliance

- More DC architectures where variable-speed gensets and flexible integration are desired

- More software (digital monitoring, predictive maintenance, energy optimisation)

- Fuel flexibility: hybrids increasingly combine with dual-fuel engines (LNG/methanol pathways) rather than competing with them

- Fuel cells are growing, but infrastructure and onboard storage remain gating factors

13) Quick glossary (engine-room friendly)

- DG: Diesel Generator

- PMS: Power Management System (genset scheduling, load sharing, protection logic)

- EMS: Energy Management System (optimises batteries/fuel cells/charging)

- VFD: Variable Frequency Drive (controls motor speed/torque)

- PTI/PTO: Power Take-In / Power Take-Off (shaft motor adding torque or generating power)

- ESS: Energy Storage System (battery + BMS + cooling + protection)

- SOC: State of Charge

- DC Bus: DC electrical distribution backbone

- Load shedding: automatic disconnection of nonessential loads to prevent blackout

- Spinning reserve: online capacity margin to absorb sudden load increases

14) FAQs

Is electric propulsion always more efficient than mechanical?

No. It’s often better at variable/low load, but mechanical can win on steady high-power transit.

What’s the biggest mistake operators make with hybrids?

Poor mode and SOC planning. The system only saves fuel if you manage it intentionally.

What’s the most common “hard” fault?

Protection/coordination problems that cause cascading trips—often triggered by a single converter or insulation issue.

Are batteries safe on ships?

They can be, but only with correct design (containment, cooling, detection), procedures, and training.

15) What to learn next (MaritimeHub link map)

To make this section “trackable” across MaritimeHub’s ENGINE learning path, the best follow-on topics are:

Energy Efficiency & Compliance (SEEMP mindset, operational measures, how hybrids support compliance goals)

Diesel-Electric Fundamentals (gensets, droop, load share, blackout recovery)

Power Electronics for Marine Engineers (rectifiers, inverters, DC link, cooling, harmonics)

Battery Safety & BMS (SOC windows, thermal runaway basics, marine containment strategies)

Shaft Generators PTI/PTO (modes, operating limits, common failure patterns)

Hybrid Fault Finding (case studies: “thrusters trip plant”, “DC link undervoltage”, “earth fault hunting”)