Principles, Efficiency, System Types, Operations & Current Trends

Engine Room · Core Machinery · Alternative Fuels

Introduction

Dual-fuel (DF) marine engines sit right in the middle of shipping’s “messy transition”: operators must meet tightening emissions requirements while fuel prices, fuel availability, and future regulations remain uncertain. DF engines solve a very specific problem: they preserve operational choice.

A DF vessel can typically run on:

- a conventional liquid fuel (MGO / VLSFO / LSFO, depending on system and compliance strategy), and

- an alternative fuel (most commonly LNG or methanol, sometimes others depending on OEM and class approvals).

That flexibility is not just “nice to have”—it changes how owners manage:

- OPEX (fuel switching when prices move),

- compliance (fuel choice by ECA/port requirements),

- risk (fallback mode when the alternative fuel is unavailable),

- asset value (futureproofing over a 20–30 year life).

This page is the MaritimeHub home reference for dual-fuel engines: one long, scrollable “everything in one place” article that all DF sub-pages link back to.

📌 Scope control

This page covers principles, system differences, efficiency/emissions trade-offs, operation, and selection logic.

Detailed maintenance, overhaul procedures, class rules, bunker procedures, specific OEM manuals, and deep emissions after-treatment are covered in their dedicated pages.

Contents

<span id=”df-1″></span>1. What “Dual-Fuel” Really Means

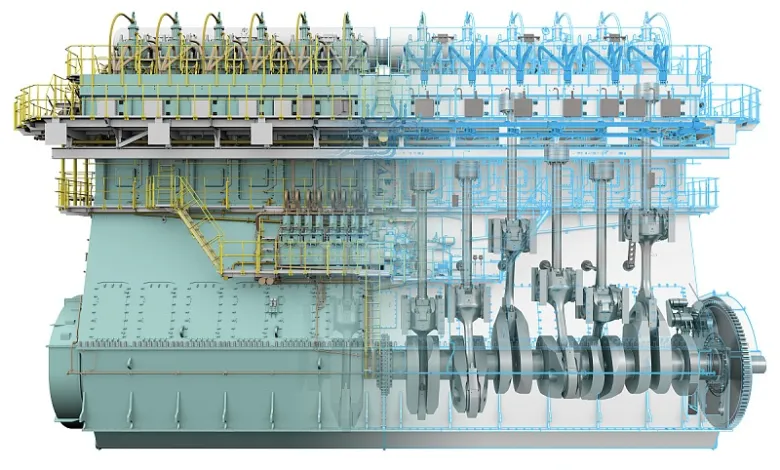

A dual-fuel marine engine is an engine that can operate on two distinct fuel types (usually one conventional and one alternative), with the ability to switch modes without losing propulsion/power continuity (within design limits).

Two important clarifications:

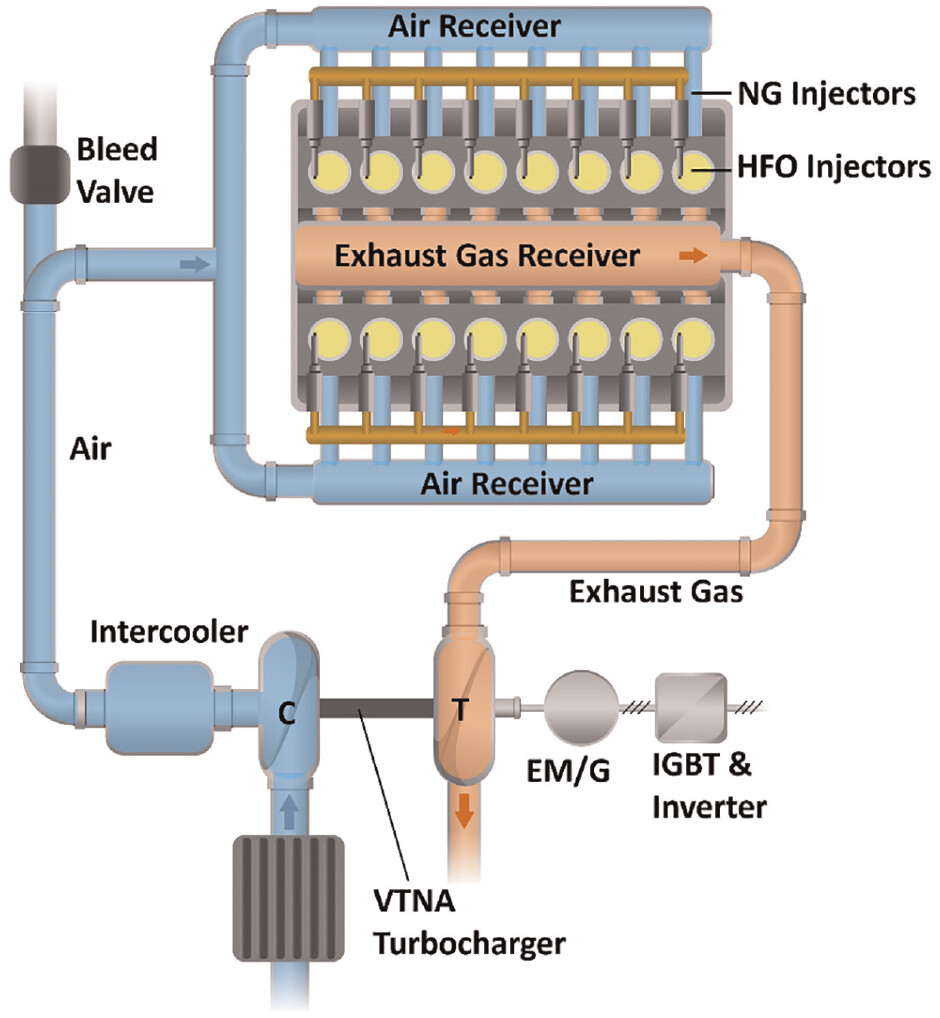

1.1 Dual-fuel is a system, not just an engine

A DF installation includes:

- fuel storage and handling (cryogenic tanks for LNG, dedicated tanks for methanol),

- conditioning (vaporisation, pressurisation, temperature control),

- safety systems (gas detection, ventilation, ESD logic),

- controls and automation (mode control, permissives, trips),

- and an engine capable of stable combustion across modes.

1.2 Dual-fuel is often “pilot fuel + main fuel”

Many DF engines still rely on a small quantity of liquid pilot fuel for reliable ignition under gas operation. Engineers must treat pilot fuel as a critical subsystem, not an afterthought.

<span id=”df-2″></span>2. Why Dual-Fuel Exists (The Engineering and Business Drivers)

Dual-fuel has grown because shipping now sits under three simultaneous pressures:

2.1 Compliance pressure

- Sulphur limits drive low-sulphur strategies.

- NOₓ rules (Tier II/Tier III in some zones) and local port rules push cleaner combustion or after-treatment.

- Carbon intensity metrics and future carbon pricing shift economics over time.

2.2 Fuel price volatility

Fuel can be 20–60% of operating cost depending on vessel type, route, and market conditions. DF engines give operators a practical lever: choose the cheaper compliant fuel when it exists.

2.3 Infrastructure and availability uncertainty

Alternative fuels are not uniformly available worldwide. DF keeps the vessel operational even if:

- LNG bunkering is not available at a port,

- methanol supply is constrained,

- or a specific fuel’s price spikes.

<span id=”df-3″></span>3. Dual-Fuel vs Mono-Fuel: What Changes Onboard

| Area | Mono-fuel | Dual-fuel (typical) |

|---|---|---|

| CAPEX | Lower | Higher (extra systems + controls + approvals) |

| OPEX | Sensitive to single fuel | Can optimise fuel choice |

| Complexity | Lower | Higher (more permissives, trips, interfaces) |

| Crew competence | Standard | Requires DF-specific training and drills |

| Maintenance | Familiar | More instrumentation + fuel system upkeep |

| Operational resilience | Lower | Higher (fallback mode) |

📌 Important: DF does not automatically mean “greener.”

It means capable of running on a potentially lower-emission fuel when you actually run it that way.

<span id=”df-4″></span>4. Combustion Concepts: Diesel-Cycle vs Otto-Cycle Gas Operation

DF engines commonly run gas in one of two combustion philosophies:

4.1 Diesel-cycle gas operation (often “high-pressure” concept)

- Gas is injected at high pressure late in compression (diesel-like timing).

- Pilot fuel initiates ignition.

- Generally strong efficiency, good load response.

- Lower methane slip tendency than premixed concepts.

Mental model: “Diesel combustion, but the main energy comes from gas.”

4.2 Otto-cycle gas operation (often “low-pressure premixed” concept)

- Gas and air are mixed prior to ignition.

- Ignition by pilot fuel or spark depending on design.

- Very clean NOₓ behaviour, but can be sensitive to transients.

- Methane slip risk can be higher if combustion is incomplete.

Mental model: “Spark-engine behaviour, but scaled to marine machinery.”

<span id=”df-5″></span>5. The Main Dual-Fuel Architectures You’ll See at Sea

5.1 Liquid fuel + LNG (most mature DF pathway)

You’ll see this on:

- container ships, tankers, car carriers,

- newbuild LNG carriers (increasingly),

- offshore tonnage.

Strengths:

- large emissions benefit vs conventional fuels (esp. SOₓ/PM),

- good route economics where LNG supply exists.

Key watchpoints:

- methane slip (depends on engine type/operation),

- cryogenic system complexity,

- tank volume and bunkering constraints.

5.2 Liquid fuel + Methanol (fast-growing pathway)

Methanol is liquid at ambient conditions → simpler storage vs LNG.

Strengths:

- easier tankage and bunkering logistics than LNG,

- very low SOₓ and low PM,

- pathway to “green methanol” as supply expands.

Key watchpoints:

- lower energy density → more volume required,

- toxicity and handling discipline,

- material compatibility and fuel system cleanliness.

5.3 Liquid fuel + LPG / other emerging combinations

Less common globally than LNG/methanol but growing in specific segments.

5.4 Multi-fuel (tri-fuel) concepts

Tri-fuel (e.g., liquid + LNG + methanol) is technically plausible but usually economically marginal today because CAPEX rises faster than the value of added optionality—unless engine costs drop or fuel markets become extremely volatile.

<span id=”df-6″></span>6. Fuel Properties That Actually Matter (LNG vs Methanol vs Liquid Fuels)

Engineers should focus on properties that change systems and operations:

6.1 Energy density (by volume)

- LNG: high energy per mass, but cryogenic; tank systems add complexity.

- Methanol: lower energy per mass and volume → you need more storage volume for the same range.

- MGO/VLSFO: high energy density and established supply chain.

6.2 Handling and hazards

- LNG: cryogenic burns, rapid phase change, flammable vapour clouds, ventilation critical.

- Methanol: toxic, flammable, invisible flame risk; exposure controls essential.

- Liquid fuels: familiar hazards, but still serious (fire, spills, H₂S in some cases, etc.).

6.3 Compatibility and cleanliness

Alternative fuels introduce new risks:

- seal compatibility,

- corrosion mechanisms,

- water management,

- contamination sensitivity.

<span id=”df-7″></span>7. Efficiency: Where Dual-Fuel Wins, Where It Doesn’t

Efficiency is not a single number. DF performance depends on:

- engine type (2-stroke vs 4-stroke DF),

- gas mode (diesel-cycle vs premixed),

- load profile,

- ambient conditions,

- tuning and maintenance condition.

7.1 Typical practical truths

- At steady loads, well-tuned DF engines can be highly competitive.

- In some DF gas modes, part-load behaviour can be less favourable than a pure diesel (depends on design).

- Fuel switching is not “free”: there are stability and control considerations during transitions.

7.2 Efficiency vs availability

Even if a fuel has theoretical efficiency benefit, it only matters if:

- you can bunker it reliably,

- you can store enough for route profile,

- and the plant runs it consistently in the intended mode.

<span id=”df-8″></span>8. Emissions: CO₂, NOₓ, SOₓ, PM — and Methane Slip

8.1 SOₓ and PM

- Gas and methanol have very low sulphur → large SOₓ reduction.

- PM typically improves significantly compared to heavy liquid fuels.

8.2 NOₓ

- Premixed/lean concepts can reduce NOₓ strongly.

- Diesel-cycle concepts may still need after-treatment for strict zones, depending on setup.

8.3 CO₂ and lifecycle reality

Tank-to-wake CO₂ can drop with gas, but well-to-wake depends on:

- fuel production pathway,

- methane slip,

- upstream leakage.

8.4 Methane slip (critical for LNG DF)

Methane slip is unburned methane reaching exhaust—important because methane is a potent greenhouse gas. Slip levels depend heavily on:

- combustion concept,

- transient operation,

- tuning and hardware condition.

📌 Detailed methane slip mechanisms and mitigation are covered in dedicated pages.

<span id=”df-9″></span>9. Fuel Switching Philosophy (Mode Management)

A DF engine is only valuable if mode management is disciplined.

9.1 When ships switch fuels in reality

- entering/leaving ECAs or port limits,

- bunkering availability constraints,

- fuel price shifts,

- operational issues (gas system trip → revert to liquid).

9.2 What “good switching” looks like

- clear permissives (pressure/temperature/flow stable),

- stable combustion before ramping load,

- controlled rate of change,

- careful monitoring of cylinder balance, EGTs, knock indicators (if used), and turbo response.

<span id=”df-10″></span>10. Safety Systems & Hazard Mindset (What’s Different for DF)

DF plants add safety layers that engineers must treat as core machinery:

- gas detection (machinery spaces, ducting, enclosures),

- ventilation interlocks,

- ESD / double block and bleed logic,

- hazardous area zoning,

- bunker station emergency response,

- ignition source control.

Chief’s mindset: treat DF systems like you treat starting air + fuel + lube oil combined:

they’re safe when engineered well and operated correctly—unsafe when shortcuts are taken.

<span id=”df-11″></span>11. Fuel Supply Systems: LNG vs Methanol (High-level)

11.1 LNG supply system (conceptual)

- storage: insulated cryogenic tanks

- conditioning: pumps/vaporisers, temperature control

- pressure management: depends on injection concept

- safety: double wall pipes, ventilation, gas safe machinery space design (varies)

11.2 Methanol supply system

- storage: conventional liquid tanks (dedicated)

- conditioning: filtration, temperature/viscosity management (as required)

- safety: leak detection, fire protection, exposure control

- delivery: fuel pumps to engine system

<span id=”df-12″></span>12. Operational Reality at Sea: Loads, Transients, and Best Practice

DF engines are most stable when:

- operating in a predictable load band,

- fuel supply parameters are stable,

- and mode transitions are planned.

12.1 Transients that challenge DF operation

- crash stop / rapid manoeuvring,

- heavy weather propeller racing,

- large electrical steps (gensets),

- DP load swings.

12.2 Best-practice watchkeeping cues

Trend, don’t just react:

- cylinder EGT spread,

- turbocharger speed / scavenge or charge pressure,

- fuel gas pressure stability (LNG),

- combustion quality indicators (knock/pressure if fitted),

- lube oil condition (dilution, contamination),

- alarms that indicate “deviation” vs “trip imminent”.

<span id=”df-13″></span>13. Typical Fault Patterns (Symptoms → Likely Causes)

13.1 High EGTs in gas mode

Common buckets:

- air deficit (filter/aftercooler/turbo fouling),

- unstable gas supply pressure,

- poor pilot fuel condition (ignition quality),

- cylinder imbalance.

13.2 Frequent mode reversion (gas → liquid)

Common buckets:

- permissive instability (pressure/temp),

- sensor faults (false trips),

- valve unit issues,

- control tuning not suited to operational profile.

13.3 Poor efficiency / high consumption

Common buckets:

- running in an inefficient load band,

- incorrect mode choice for profile,

- degraded air system,

- combustion instability forcing conservative tuning.

📌 Full DF troubleshooting workflows are covered in dedicated pages.

<span id=”df-14″></span>14. Selecting DF Engines Under Fuel Price Uncertainty (Practical Takeaways)

You referenced Wu et al. (2023), which models multi-fuel engine selection under fuel price uncertainty and ties together:

- engine choice (CAPEX),

- fuel choice (OPEX),

- fleet deployment,

- and speed optimisation.

14.1 The decision logic that matters (translated to operator language)

Mono-fuel is often cheapest when:

- fuel prices are stable,

- compliance can be met cheaply (e.g., low sulphur liquid fuels),

- and the vessel’s operating profile is predictable.

Dual-fuel becomes attractive when:

- relative fuel prices swing meaningfully over time,

- the DF CAPEX premium is not extreme,

- the route has reliable access to the alternative fuel,

- and the operation can actually exploit the flexibility (not forced into one mode always).

Tri-fuel becomes attractive only if:

- CAPEX reduces substantially or

- fuel price uncertainty is large enough that extra flexibility is repeatedly monetised.

14.2 The hidden lever: speed + deployment

The paper’s key operational insight is that engine choice isn’t isolated:

- slow steaming can reduce fuel burn,

- but may require more ships to maintain schedule frequency,

- which changes the investment vs fuel trade-off.

Engineering takeaway: DF value increases when your operations team can actively use:

- speed policy,

- route deployment,

- and fuel switching strategy

as a combined system.

<span id=”df-15″></span>15. Current Trends (2020s → 2030s): What the Industry Is Doing

15.1 LNG DF: mature and widely deployed

- strong uptake in deep-sea segments with LNG infrastructure,

- ongoing focus on methane slip measurement and reduction,

- OEM improvements in combustion control.

15.2 Methanol DF: accelerating fast

- simpler logistics than LNG,

- strong momentum from “green methanol” narratives,

- increasing newbuild specifications and fuel supply investments.

15.3 Multi-fuel and “fuel-ready” designs

- shipowners increasingly demand “ready” not “locked-in”

- tank space planning, safety zoning, modularity

- digital optimisation tools to choose fuels under uncertainty

15.4 Digitalisation

- better sensors, better controls, better predictive maintenance

- optimisation shifting from “chief’s experience” to “chief + analytics”

<span id=”df-16″></span>16. DF vs Alternatives: Two-Stroke Diesel, Gas Turbines, Batteries, Fuel Cells

- Two-stroke diesel: unmatched for steady propulsion efficiency; DF versions exist and are central to modern deep-sea strategy.

- Gas turbines: high power density, fast response; fuel flexibility differs; more common in naval/high speed contexts.

- Batteries: excellent for short sea, ports, hybrid peaks; not a universal deep-sea replacement.

- Fuel cells: promising but constrained by fuel supply chains and onboard system maturity.

Bottom line: DF engines are one of the few options that scale today across many vessel types while preserving flexibility.

<span id=”df-17″></span>17. What to Learn Next (MaritimeHub Link Map)

This page should link out to the DF “system pages”:

- LNG Fuel Systems (Marine)

- Methanol as a Marine Fuel

- Gas Safety, Detection & ESD Logic

- Methane Slip: Causes, Measurement, Mitigation

- Dual-Fuel Combustion Modes (Diesel-cycle vs Otto-cycle)

- DF Engine Control & Mode Transition Best Practice

- DF Troubleshooting: Symptom → Cause Flowcharts

- Fuel Economics for Engineers (simple models + real examples)

Final Chief Engineer Takeaway

Dual-fuel engines are not about picking the “best fuel.”

They are about keeping the ship economically and operationally viable while the industry decides what the future fuel landscape will actually be.

Tags

dual-fuel marine engine · LNG dual fuel · methanol marine engines · multi-fuel ships · fuel price uncertainty · green shipping · marine decarbonisation