Principles, Operation, Design & Marine Application

Engine Room · Core Machinery · Thermal Power Systems

Introduction

Steam turbines are one of the most enduring and powerful prime movers ever deployed at sea. While often regarded as legacy technology, they remain operationally critical in modern maritime engineering—particularly in high-power, high-reliability, and fuel-flexible applications.

From naval vessels and LNG carriers to turbo-generators and cargo pumping systems, steam turbines continue to prove their value through:

- Smooth, continuous power delivery

- Exceptional reliability and longevity

- High power density

- Fuel and heat-source adaptability

- Compatibility with closed-loop thermal systems

This page serves as the authoritative MaritimeHub reference for marine steam turbines. It explains how steam turbines work, why they are still used, and how engineers should understand, operate, and maintain steam turbine plants in modern ships.

.

Contents

- What Is a Marine Steam Turbine?

- Why Steam Turbines Still Matter in Modern Shipping

- Fundamental Operating Principle

- Steam Propulsion System Architecture

- Steam Turbines in LNG Carriers

- Types of Marine Steam Turbines

- Steam Flow, Staging & Power Control

- Condensing Systems & Closed-Loop Operation

- Mechanical Design & Reduction Gearing

- Control, Monitoring & Protection

- Operational Characteristics at Sea

- Maintenance Philosophy & Reliability

- Steam Turbines vs Diesel & Gas Turbines

- Modern Advancements in Marine Steam Turbines

- How This Page Anchors the Steam Systems Section

1. What Is a Marine Steam Turbine?

A marine steam turbine is a rotary prime mover that converts the thermal energy of high-pressure steam into mechanical rotational energy by expanding steam across rows of turbine blades.

Unlike reciprocating engines:

- Power delivery is continuous

- There are no pistons, connecting rods, or crankshafts

- Rotational speed is high and smooth

- Vibration levels are low

A steam turbine converts energy through velocity and pressure change, not through intermittent combustion events.

2. Why Steam Turbines Still Matter in Modern Shipping

Steam turbines persist because they solve specific marine engineering problems extremely well.

2.1 Enduring Power and Reliability

Steam turbines:

- Have very few moving parts

- Operate with uniform torque

- Experience minimal mechanical stress

- Can run continuously for months

This results in:

- Long service life

- Reduced vibration and noise

- High availability for mission-critical vessels

These characteristics make them ideal for:

- Aircraft carriers

- LNG carriers

- Turbo-generator systems

- Large auxiliary machinery

2.2 Fuel Adaptability and Decarbonisation Potential

The core strength of steam propulsion lies in fuel and heat-source flexibility.

Steam turbines do not burn fuel directly. They depend on steam generation, which allows:

- Oil-fired boilers

- Gas-fired boilers

- Boil-off gas (LNG) utilisation

- Biofuels and synthetic fuels

- Nuclear heat sources (naval vessels)

- Waste heat recovery

Changing the fuel does not require changing the turbine—only the heat source.

This positions steam systems as a future-compatible platform for decarbonisation.

3. Fundamental Operating Principle

Steam turbines operate on a simple but powerful concept:

- Steam is generated at high pressure and temperature in a boiler

- Steam expands through stationary nozzles, increasing velocity

- High-velocity steam strikes moving blades

- Momentum transfer causes rotor rotation

- Steam exits at lower pressure and temperature

The turbine extracts energy through:

- Change in steam velocity (impulse)

- Change in steam pressure (reaction)

- Or a combination of both

Impulse vs Reaction Turbines

| Feature | Impulse Turbine | Reaction Turbine |

|---|---|---|

| Pressure Drop Location | Occurs only in stationary nozzles | Occurs in both fixed and moving blades |

| Blade Channel Area | Constant cross-section | Varying cross-section |

| Blade Profile Type | Profile / bucket-type blades | Aerofoil-type blades |

| Steam Admission | Partial or restricted admission | Full (all-round) admission |

| Fixed Blade Function | Nozzles contained in diaphragm | Fixed blades act as guide vanes |

| Space Requirement | Occupies less space for same power | Occupies more space for same power |

| Efficiency Characteristics | High efficiency in initial (high-pressure) stages | High efficiency in final (low-pressure) stages |

| Typical Power Range | Small to moderate power | Medium to high power |

| Manufacturing Complexity | Simpler blade design, lower cost | More complex blade geometry, higher cost |

| Steam Velocity | High steam velocity | Lower steam velocity |

| Typical Marine Use | HP stages, control stages | LP stages, propulsion turbines |

Engineering Interpretation (What Actually Matters)

Impulse Turbines

- Extract energy primarily from kinetic energy

- Steam jets strike blades at high velocity

- Pressure remains nearly constant across moving blades

- Well suited for high-pressure, small volume steam

Impulse stages are ideal where pressure drop must be controlled precisely, such as initial stages of marine propulsion turbines.

Reaction Turbines

- Extract energy from both pressure drop and velocity change

- Moving blades act like aerofoils

- Continuous expansion through blade rows

- Require careful sealing and clearance control

Reaction stages excel in low-pressure, high-volume steam, making them ideal for LP sections of marine turbines.

4. Steam Propulsion System Architecture

Steam turbines are part of a complete thermal power plant, not standalone machines.

4.1 Typical Steam Propulsion Flow

- Fuel (or heat source) heats boiler water

- Superheated steam is produced

- Steam drives:

- Main propulsion turbine

- Turbo-generators

- Exhaust steam enters condenser

- Steam condenses back to water

- Condensate is treated and reused

This is a closed-loop Rankine cycle.

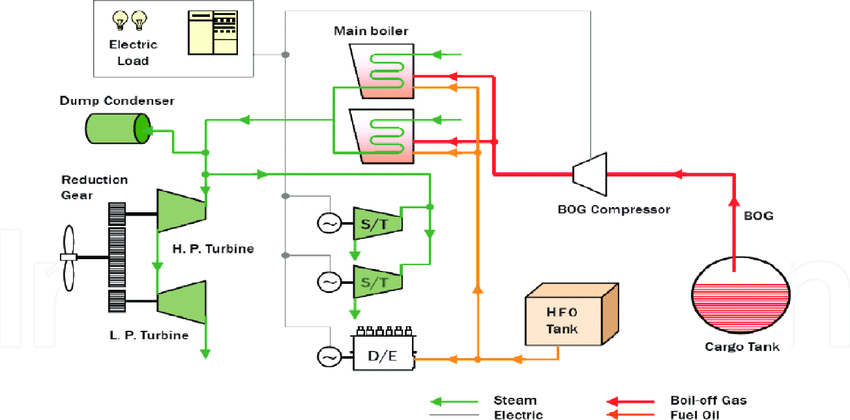

5. Steam Turbines in LNG Carriers

5.1 Why LNG Carriers Used Steam Propulsion

LNG cargo continuously evaporates, producing boil-off gas (BOG):

- ~0.1% of cargo volume (ballast)

- ~0.15% of cargo volume (laden)

Steam plants offered a natural solution:

- Burn BOG in boilers

- Generate steam

- Propel the ship and generate power

This made steam propulsion:

- Safe

- Efficient

- Cargo-compatible

The cargo itself becomes part of the energy system.

Most LNG carriers built pre-2015 used steam propulsion, with diesel generators as backup.

6. Types of Marine Steam Turbines

Steam turbines are classified by several criteria:

6.1 By Principle of Operation

- Impulse turbines – pressure drop in nozzles only

- Reaction turbines – pressure drop across fixed and moving blades

- Impulse-reaction turbines – combined approach (common in marine use)

6.2 By Steam Flow Direction

- Axial flow – steam parallel to shaft (most marine turbines)

- Radial flow – steam perpendicular to shaft (specialised use)

6.3 By Exhaust Condition

- Condensing turbines – exhaust steam condensed (propulsion, power generation)

- Back-pressure turbines – exhaust steam used for heating or processes

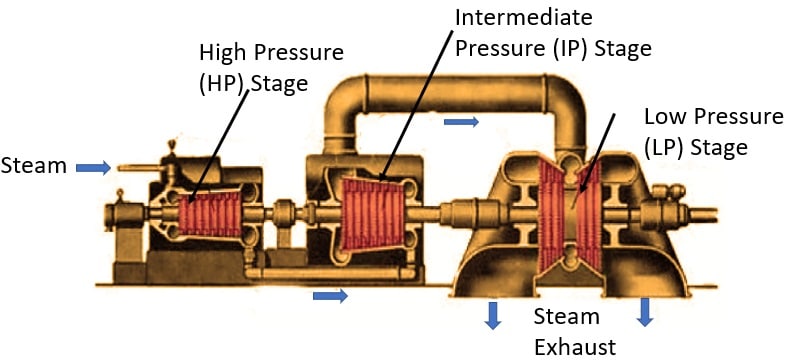

6.4 By Pressure & Casing Arrangement

- Single-stage / multi-stage

- Single casing

- Tandem compound

- Cross compound (HP and LP turbines on separate shafts)

7. Steam Flow, Staging & Power Control

Steam turbines control power output by:

- Regulating steam admission

- Adjusting nozzle opening

- Using multiple stages for efficiency

Multi-stage expansion:

- Reduces blade stress

- Improves thermal efficiency

- Allows large power extraction

Key difference vs diesel

Turbine power is controlled by steam flow, not fuel injection timing.

8. Condensing Systems & Closed-Loop Operation

Condensers:

- Convert exhaust steam back to water

- Create vacuum at turbine exhaust

- Increase turbine efficiency

Benefits of condensation:

- Higher thermal efficiency

- Reduced steam consumption

- Water conservation

Condenser performance directly affects turbine power and efficiency.

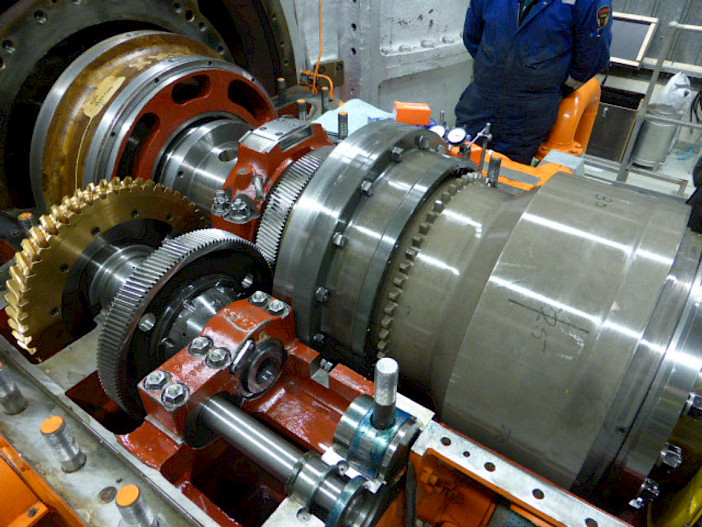

9. Mechanical Design & Reduction Gearing

Steam turbines operate at:

- Thousands of RPM (HP turbine)

- Hundreds of RPM (LP turbine)

Propellers require:

- ~80–120 RPM

This mismatch is handled by:

- Double-reduction gearboxes

- Tandem articulated gearing

- Double helical gears

Example (typical LNG carrier):

- HP turbine ≈ 4,800 RPM

- LP turbine ≈ 3,200 RPM

- Propeller ≈ 85 RPM

10. Control, Monitoring & Protection

Steam turbine plants monitor:

- Steam pressure and temperature

- Turbine speed

- Vibration

- Bearing temperatures

- Condenser vacuum

- Lubrication system health

Modern systems include:

- Digital monitoring

- Alarm trending

- Predictive maintenance tools

11. Operational Characteristics at Sea

Steam turbine plants:

- Prefer steady operation

- Have slow response compared to diesels

- Require skilled plant management

- Are highly stable once on load

Watchkeeping focus:

- Boiler water chemistry

- Steam quality

- Condenser vacuum

- Lubrication condition

12. Maintenance Philosophy & Reliability

Key maintenance priorities:

- Rigorous feedwater treatment

- Blade inspection for erosion

- Bearing and oil system care

- Condenser cleanliness

Steam turbines fail slowly and predictably when monitored correctly.

13. Steam Turbines vs Diesel & Gas Turbines

Steam Turbine vs Diesel Engine

- Diesels: higher part-load efficiency

- Steam turbines: smoother operation, fuel flexibility, high power

Steam Turbine vs Gas Turbine

- Gas turbines: rapid response, high power-to-weight

- Steam turbines: broader fuel compatibility, better steady-state efficiency

14. Modern Advancements in Marine Steam Turbines

14.1 Digital Twin Technology

- Virtual replicas for real-time monitoring

- Predictive maintenance

- Performance optimisation

14.2 Additive Manufacturing

- Complex blade geometries

- Improved aerodynamics

- Reduced material waste

14.3 Supercritical CO₂ (sCO₂) Turbines

- Compact, high-efficiency designs

- Higher thermal efficiency than steam

- Potential future marine applications

14.4 Waste Heat Recovery Integration

- Combined Gas & Steam (COGAS) systems

- Improved overall plant efficiency

- Reduced emissions

15. How This Page Anchors the Steam Systems Section

This page is the conceptual foundation for all steam-related content on MaritimeHub, including:

- Marine boilers

- Water treatment systems

- Condensers

- Turbo-generators

- LNG boil-off gas handling

- Steam plant faults and troubleshooting

A steam turbine is not obsolete—it is thermodynamically elegant, mechanically reliable, and strategically flexible.

When fuel diversity, power density, and reliability matter most, steam propulsion remains unmatched.

Tags

marine steam turbine · steam propulsion · LNG carrier propulsion · marine boilers · turbo generator · thermal power systems