Principles, Operation, Design & Marine Application

Introduction

Two-stroke engines form the backbone of deep-sea propulsion.

From large container vessels and tankers to bulk carriers and LNG ships, slow-speed two-stroke diesel engines are trusted because they deliver:

- High efficiency

- Massive torque at low speed

- Continuous, reliable operation

- Excellent fuel economy for long voyages

This page explains how two-stroke marine engines work, why they are designed the way they are, and how engineers should think about them in operation.

📌 Scope note

This page explains principles, design logic, and operation.

Component overhauls, faults, tuning, emissions, and calculations are covered in their dedicated system pages.

Contents

- What Defines a Two-Stroke Marine Engine?

- Why Two-Stroke Engines Dominate Main Propulsion

- The Two-Stroke Operating Cycle (Step by Step)

- Scavenging: The Heart of the Two-Stroke Engine

- Air Supply & Turbocharging

- Fuel Injection & Combustion

- Lubrication Philosophy in Two-Stroke Engines

- Cooling & Thermal Control

- Mechanical Design Features

- Control, Monitoring & Protection

- Operational Characteristics at Sea

- Common Misconceptions About Two-Stroke Engines

- How This Page Connects to the Rest of the Engine Room

1. What Defines a Two-Stroke Marine Engine?

A two-stroke marine engine completes a full operating cycle in one crankshaft revolution.

This means:

- One power stroke every revolution

- No separate intake or exhaust strokes

- Gas exchange happens through ports in the cylinder liner

Key defining characteristics:

- Slow rotational speed (typically 60–120 RPM)

- Large bore, long stroke

- Direct coupling to the propeller

- Uniflow scavenging

- Continuous-duty operation

⚙️ “Two-stroke” refers to the cycle — not simplicity.

2. Why Two-Stroke Engines Dominate Main Propulsion

Two-stroke engines are chosen not because they are old — but because they are optimal for marine propulsion.

Key advantages

- High thermal efficiency

- Excellent fuel economy

- High torque at low RPM

- No reduction gearbox required

- Simpler power transmission

- Better propeller efficiency

Marine reality

Ships require:

- Continuous thrust

- Predictable response

- Long maintenance intervals

- Operation far from shore support

Two-stroke engines are built around these realities.

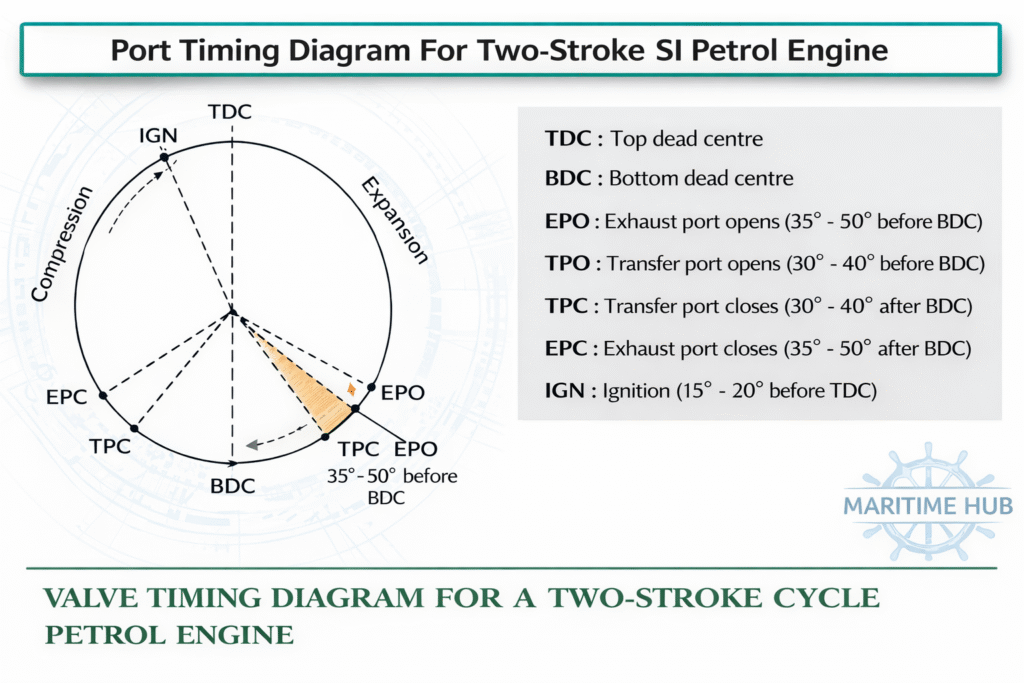

3. The Two-Stroke Operating Cycle (Step by Step)

Unlike four-stroke engines, all major events occur within one piston movement up and down.

Upward Stroke (Compression)

- Exhaust valve closes

- Fresh air is trapped in the cylinder

- Air is compressed to high pressure and temperature

Fuel Injection & Combustion

- Fuel is injected near TDC

- Self-ignition occurs

- Combustion pushes piston downward

Downward Stroke (Power + Gas Exchange)

- Exhaust valve opens

- Exhaust gases begin to leave

- Scavenge ports open

- Fresh air enters, pushing exhaust out

- Cycle repeats

4. Scavenging: The Heart of the Two-Stroke Engine

Scavenging is the process of:

- Removing exhaust gases

- Replacing them with fresh air

- Without mixing excessively

Uniflow scavenging (marine standard)

- Air enters through liner ports

- Exhaust exits via cylinder head valve

- Gas flow is one-directional

Benefits:

- Efficient gas exchange

- Better combustion

- Reduced thermal stress

- Improved emissions performance

📌 Scavenging faults affect power, temperatures, fuel consumption, and emissions.

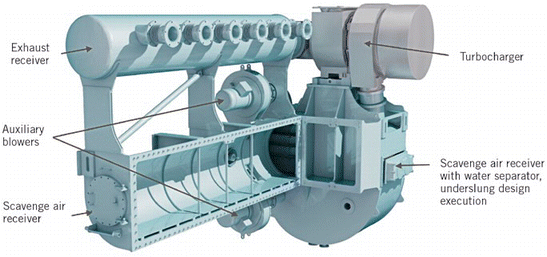

5. Air Supply & Turbocharging

Two-stroke engines cannot draw in air naturally.

They rely entirely on:

- Turbochargers

- Scavenge air receivers

- Auxiliary blowers (low load)

Why turbocharging is essential

- Provides scavenge air pressure

- Ensures cylinder filling

- Maintains combustion stability

At low loads:

- Auxiliary blowers support airflow

- Turbocharger efficiency is reduced

6. Fuel Injection & Combustion

Two-stroke engines use high-pressure, timed fuel injection.

Key principles:

- Injection occurs over a short crank angle

- Fuel atomisation is critical

- Combustion must be controlled, not explosive

Combustion quality depends on:

- Injection timing

- Fuel quality

- Scavenge air temperature

- Compression pressure

⚠️ Poor combustion leads to:

- High exhaust temperatures

- Piston crown damage

- Liner wear

- Emissions issues

7. Lubrication Philosophy in Two-Stroke Engines

Unlike four-stroke engines, lubrication is divided by function.

Main lubrication systems

- System oil (bearings, crankcase)

- Cylinder oil (liner & rings)

Cylinder oil:

- Is injected directly

- Is partially consumed

- Neutralises sulphur acids

- Protects liner surfaces

📌 Cylinder lubrication strategy is critical and fuel-dependent.

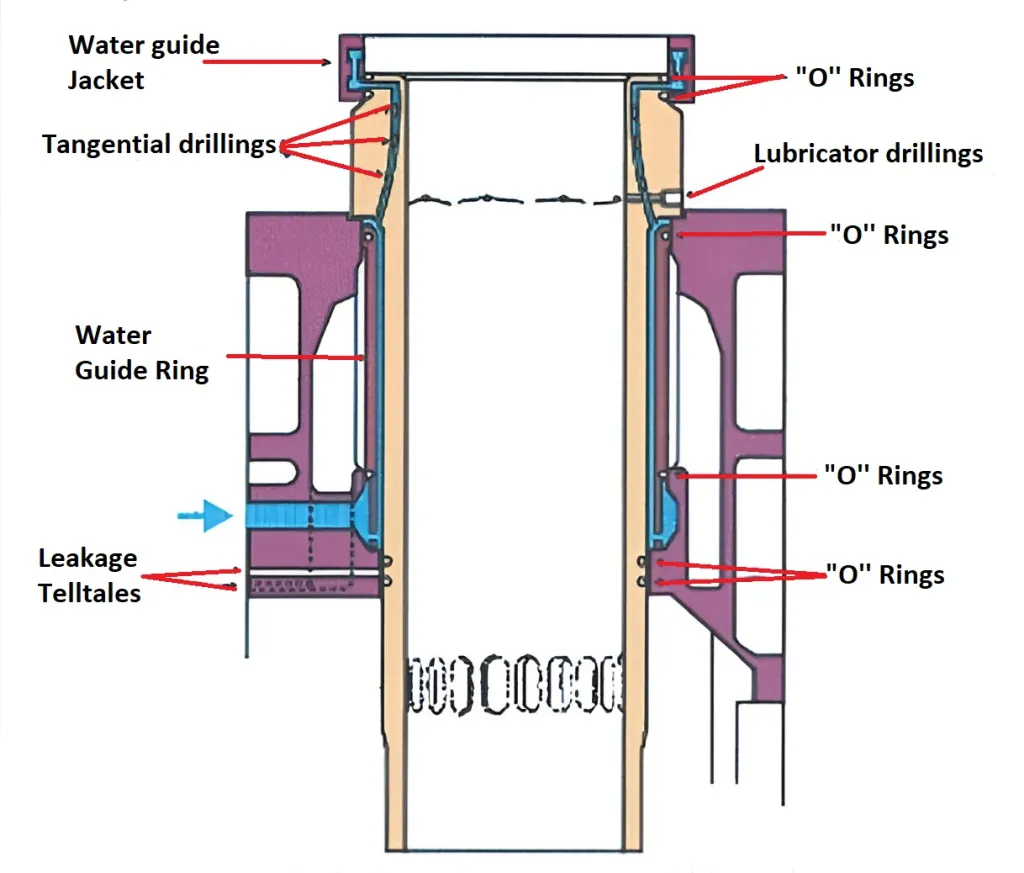

8. Cooling & Thermal Control

Two-stroke engines operate under extreme thermal loads.

Cooling is applied to:

- Cylinder liners

- Cylinder covers

- Exhaust valves

- Pistons

Design priorities:

- Prevent thermal cracking

- Control metal temperatures

- Maintain material strength

9. Mechanical Design Features

Two-stroke engines are built for strength and longevity.

Typical features:

- Crosshead design

- Long connecting rods

- Separate crankcase and cylinder spaces

- Heavy bedplate and frame box

Benefits:

- Reduced side thrust

- Improved liner life

- Easier maintenance access

- Better oil control

10. Control, Monitoring & Protection

Modern two-stroke engines use:

- Electronic governors

- Cylinder pressure monitoring

- Exhaust temperature monitoring

- Safety shutdowns

Critical monitored parameters:

- Exhaust temperatures

- Scavenge air pressure

- Lubrication flow

- Bearing temperatures

⚠️ Alarms indicate deviation from normal, not failure itself.

11. Operational Characteristics at Sea

Two-stroke engines:

- Respond slowly to load changes

- Prefer steady operation

- Require careful manoeuvring control

- Are sensitive to fuel quality

Engineers must understand:

- Load limits

- Thermal stabilisation time

- Slow steaming effects

- Minimum load constraints

12. Common Misconceptions About Two-Stroke Engines

❌ “Two-stroke engines are simpler”

✔ They are conceptually simpler but mechanically massive

❌ “They are outdated technology”

✔ They are continuously evolving

❌ “They are inefficient”

✔ They are among the most efficient heat engines ever built

13. How This Page Connects to the Rest of the Engine Room

This page is the conceptual anchor for:

- Fuel systems

- Lubrication systems

- Starting & reversing

- Performance & tuning

- Emissions control

- Fault diagnosis

📌 If a problem exists on a two-stroke engine, it always traces back to principles explained here.

Tags

two-stroke marine engine · slow speed diesel · main engine propulsion · marine engineering training · engine room fundamentals

Next logical steps (recommended)

From here, users should move to:

- Fuel Injection Systems

- Scavenging & Air Systems

- Starting & Reversing

- Performance & Tuning

- Common Two-Stroke Faults